Basket filters are used on oil or other liquid pipelines to filter debris in the pipelines. The filter hole area is 2-3 times larger than the diameter pipe area. Far exceeds the filtration area of Y-type and T-type filters. The filter structure is different from other filters. It is named basket filter because it is shaped like a basket.

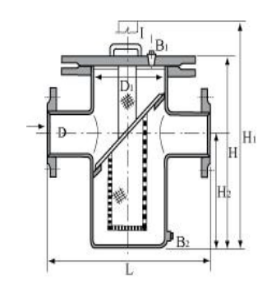

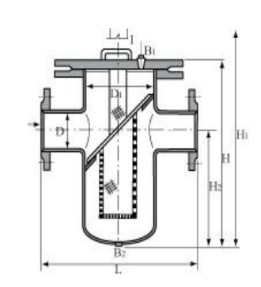

flat bottom Arc bottom

Advantage

1) Wide range of application. Basket filters are suitable for chemical, petrochemical, food, pharmaceutical and other industries, and can handle various weakly corrosive or corrosive materials, such as water, oil, chemicals, food and beverages, etc.

2) Simple structure and easy maintenance. The basket filter is mainly composed of screen, shell, inlet and outlet, sealing ring, etc. It is easy to disassemble and clean, reducing maintenance costs.

3) High filtration efficiency. The basket filter adopts mesh filtration, which can efficiently filter fine particulate matter, reduce jamming, and has a large dirt holding capacity and small resistance loss.

4) Easy to operate and clean. The basket filter supports manual or automatic cleaning without downtime, and the cleaning and maintenance process is simple, reducing the difficulty of operation.

5) Long service life. Basket filters are made of corrosion-resistant materials, such as stainless steel, aluminum alloy, etc., and have a long service life.

6) Low maintenance cost. The basket filter has few wearing parts and requires no additional consumables, which reduces operation and maintenance costs.

7) Small footprint. The basket filter has a compact structure, is easy to install and saves space.

8) Stable and reliable operation. The basket filter adopts a built-in transmission device and is sealed and isolated to prevent damage to the motor or components.

9) Stable filtration effect and not easy to block. The basket filter operates with low noise and can effectively extend the service life of the equipment.