1、Valve before installation should do the following.

①. Carefully check whether usage of valve and its performance specifications;

②. To check whetherthere issundry,valvechannel and sealing surface and keep clear of in time;

③. Afteropeningthe valve toinstallintimedon’tloose any fastening screw on the valve at random;

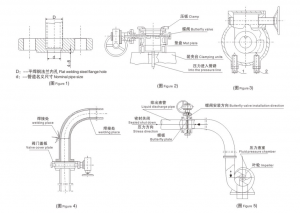

④. Multilevel metal sealing and soft sealing butterfly valve with cast ironstandardflange, the rest with special flange butterfly valve (see figure 1)

⑤. Installation, debugging personnel should carefully read the instruction manual and pneumatic, electric and other specifications, in accordance with themanual,wiring diagramfor installation, operation, commissioning and wiring;

⑥. Usertesting. be sure to use the flange to clamp installed on both ends or pressure test (see figure 2);

⑦.Butterfly valve installed in the closed, valve channel should be used when welding plate blocks (see figure 4). Prevent the particles and sundry rub sealing surface.

2、Butterflv valve can be installed at anv Angle ofthe line. but can’tflip Usuallv in the form of vertical and horizontal installation.

3、Butterfly valve is aone-way commonly use, pay attention to the arrow onthe valve body for sealing off the medium pressure direction. (see figure 5)

4、Flange butterfy valve installed in the end of the linethe end of the side should be equipped with flange. in order to prevent the sealing ring squeeze a bit.

5、The products are pass strict inspection before they go out and test, but there are also individual product vibration screw dislocation in transit, should be readjusted. Adjustment should be according to the shown in figure 3. If butterfly plate edition closed lax, will be 2 screw counterclockwise, a little rotating disc to seal position, right after the lock nut: if the butterfly plate closed (or butterfly plate doesn’t open) screw clockwise 2 should be a little, open the disc to close seal position, right after the lock nut. (see figure 3)

6、Electric butterfly valve factory, has will control institutions opening and closing schedule set, to prevent wrong orientation when power on, the user before turning on the power supply for the first time, want to manually open to half open position first, then point switch, check the dial direction valve is open in the same direction.