| Face to Face: |

API609 |

| Test and Inspection: |

API598 |

| Top Flange Standard: |

ISO5211 |

| Epoxy Spraying: |

RAL 5005 or customized |

| Documents Service: |

FORM E Certificate of Origin/Certificate of Material/Pressure Testing Report |

| Working Temperature: |

-20℃~120℃ |

|

Nominal Pressure: |

PN10/PN16/CLASS125/CLASS150/10K/5K |

|

Available Material: |

|

| Body Material: |

Ductile Iron/WCB/CF8/CF8M |

| Disc Material: |

CF8+PTFE lined/CF8M+PTFE lined |

| Shaft Material: |

SS304/SS316/2Cr13 |

| Seat Material: |

PTFE |

|

Quality Standard: |

|

| Design & Manufacture Standard: |

API 609 |

| Face to Face Dimension Standard: |

API 609 |

| Test & Inspection Standard: |

API 598 |

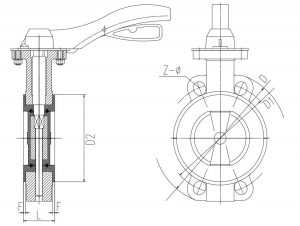

The PTFE Lined Butterfly Valve adopts a fluoroplastic coated disc with a spherical sealing surface, and a silicon rubber gasket at the base of the valve seat to adjust the sealing performance of the valve; The valve is light in operation, tight in sealing performance and long in service life. It can be used for quick cut-off or flow regulation. Suitable for occasions requiring reliable sealing and good adjustment characteristics.

The valve body adopts the split type, and the sealing at both ends of the valve shaft is controlled by adding fluorine rubber to the rotating base surface between the disc and the seat, so as to achieve compact structure, beautiful appearance, reasonable process and reliable performance. Ensure that the valve shaft does not contact with the fluid medium in the cavity. It is convenient to replace the valve shaft. The valve can be completed without detaching from the pipeline.

| DN | Technical Dimension size | Technical Dimension size | Reference Value | ||||||||||||

| L | D | D1 | D2 | F | B | Z-Φd | D | D1 | D2 | F | B | Z-Φd | Net weight (kg) |

||

| mm | inch | Wafer | PN10 (1.0MPa) | PN16 (1.6MPa) | |||||||||||

| 40 | 1 1/2 | 33 | 150 | 110 | 85 | 3 | 18 | 4-Φ18 | 150 | 110 | 85 | 3 | 18 | 4-Φ18 | 5.8 |

| 50 | 2 | 43 | 165 | 125 | 100 | 3 | 18 | 4-Φ18 | 165 | 125 | 100 | 3 | 18 | 4-Φ18 | 5.8 |

| 65 | 2 1/2 | 46 | 185 | 145 | 120 | 3 | 18 | 4-Φ18/8-Φ18 | 185 | 145 | 120 | 3 | 18 | 4-Φ18/8-Φ18 | 6.5 |

| 80 | 3 | 46 | 200 | 160 | 135 | 3 | 20 | 8-Φ18 | 200 | 160 | 135 | 3 | 20 | 8-Φ18 | 7.5 |

| 100 | 4 | 52 | 220 | 180 | 155 | 3 | 20 | 8-Φ18 | 220 | 180 | 155 | 3 | 20 | 8-Φ18 | 9 |

| 125 | 5 | 56 | 250 | 210 | 185 | 3 | 22 | 8-Φ18 | 250 | 210 | 185 | 3 | 22 | 8-Φ18 | 11 |

| 150 | 6 | 56 | 285 | 240 | 210 | 3 | 22 | 8-Φ22 | 285 | 240 | 210 | 3 | 22 | 8-Φ22 | 15 |

| 200 | 8 | 60 | 340 | 295 | 265 | 3 | 24 | 8-Φ22 | 340 | 295 | 265 | 3 | 24 | 12-Φ22 | 21.5 |

| 250 | 10 | 68 | 395 | 350 | 320 | 4 | 26 | 12-Φ22 | 405 | 355 | 320 | 4 | 26 | 12-Φ26 | 30 |

| 300 | 12 | 78 | 445 | 400 | 370 | 4 | 26 | 12-Φ22 | 460 | 410 | 370 | 4 | 28 | 12-Φ26 | 44.5 |

| 350 | 14 | 78 | 505 | 460 | 430 | 4 | 26 | 16-Φ22 | 520 | 470 | 430 | 4 | 30 | 16-Φ26 | 62.5 |

| 400 | 16 | 102 | 565 | 515 | 480 | 4 | 26 | 16-Φ26 | 580 | 525 | 480 | 4 | 32 | 16-Φ30 | 128.5 |

| 450 | 18 | 114 | 615 | 565 | 530 | 4 | 28 | 20-Φ26 | 640 | 585 | 550 | 4 | 40 | 20-Φ30 | 159 |

| 500 | 20 | 127 | 670 | 620 | 580 | 4 | 28 | 20-Φ26 | 715 | 650 | 610 | 5 | 44 | 20-Φ33 | 190 |

| 600 | 24 | 154 | 780 | 725 | 680 | 5 | 34 | 20-Φ30 | 840 | 770 | 720 | 5 | 54 | 20-Φ36 | 235 |

| 700 | 28 | 165 | 895 | 840 | 795 | 5 | 34 | 24-Φ30 | 910 | 840 | 759 | 5 | 42 | 24-Φ36 | 395 |

| 800 | 32 | 190 | 1015 | 950 | 900 | 5 | 36 | 24-Φ33 | 1025 | 950 | 900 | 5 | 42 | 24-Φ39 | 495 |

| 900 | 36 | 203 | 1115 | 1050 | 1000 | 5 | 38 | 28-Φ33 | 1125 | 1050 | 1000 | 5 | 44 | 28-Φ39 | 560 |

| 1000 | 40 | 216 | 1230 | 1160 | 1115 | 5 | 38 | 28-Φ36 | 1255 | 1170 | 1110 | 5 | 46 | 28-Φ42 | 1000 |

| 1200 | 48 | 254 | 1455 | 1380 | 1330 | 5 | 44 | 32-Φ39 | 1485 | 1390 | 1330 | 5 | 52 | 32-Φ48 | 1300 |

The products are widely used in the transportation of liquids and gases (including steam) in various types of industrial pipelines, especially in the occasions with severely corrosive media such as sulfuric acid, hydrofluoric acid, phosphorus, acid, chlorine gas, strong alkali, aqua regia, etc.

Any concentration of acid, alkali, chlorine, hydrogen sulfide strong oxidant, concentrated nitric acid, etc.

1. Centerline structure, the whole disc and the seat are concentric within a 360° circle (centerline), with bidirectional sealing function;

2. Four-stage loading elastic seal to ensure zero leakage;

3. The radial direction of the valve shaft is sealed by a combination of O-ring and metal gasket;

4. The seat is inlaid in the groove of the body with elastic strips.

Petroleum, Food, Medicine, Chemical Indsutry, Textile & Papermaking, Municipal administration

Helping you with our 10 years experiences of valve products industry