Butterfly valves are widely used. Common butterfly valves can be divided into two types: wafer butterfly valve and flange butterfly valve.

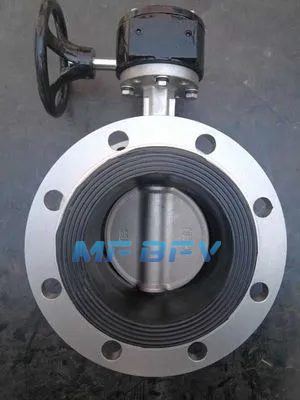

Wafer butterfly valves do not have flanges. Common wafer butterfly valves have only four bolt holes. When installing, two flanges are needed to clamp the wafer butterfly valve in the middle, and then connect it to the pipeline through bolts. The wafer butterfly valve has a shorter structure length, smaller volume, and lighter weight, so it has advantages in small-diameter valves and has lower costs.

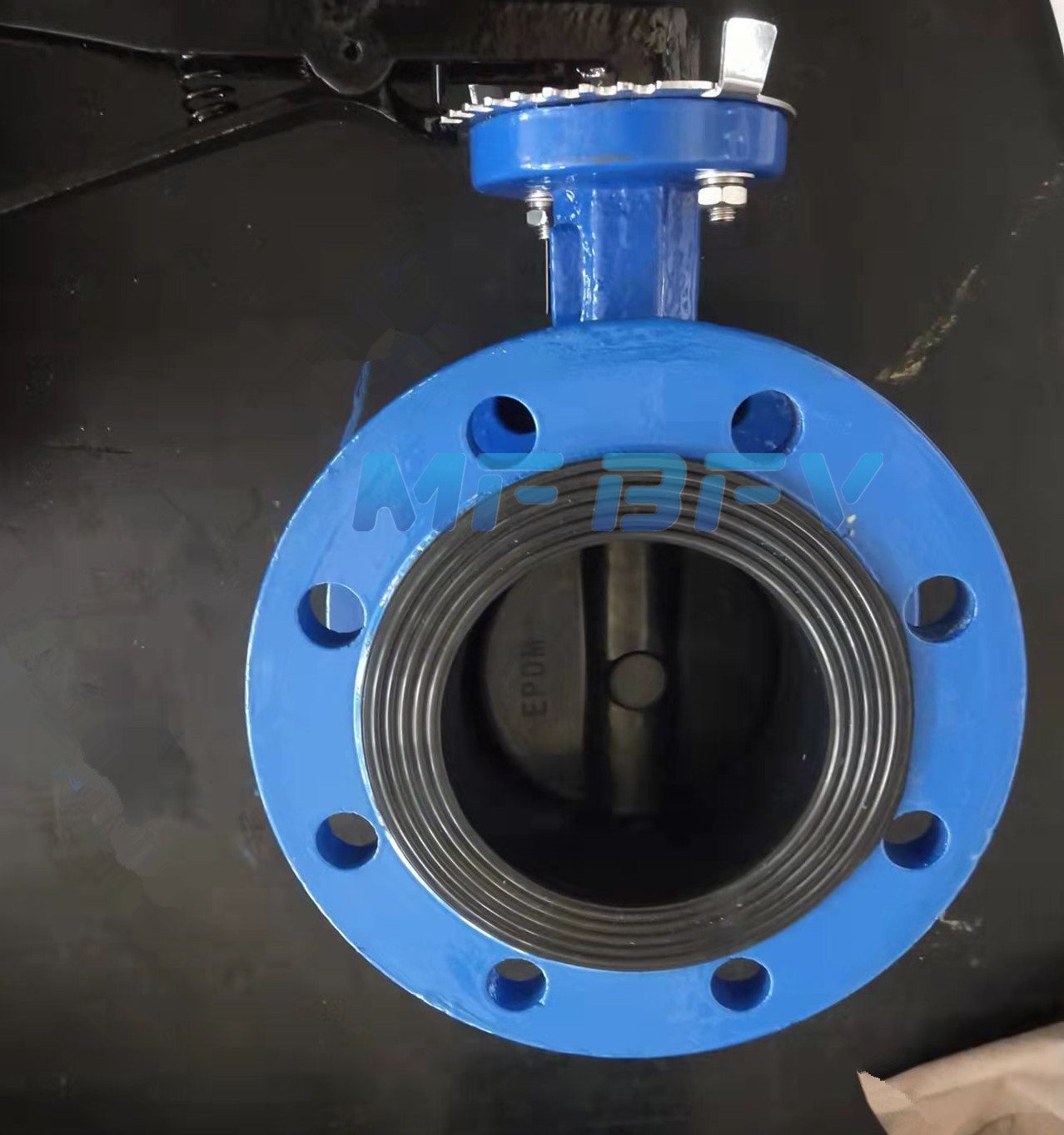

Flange butterfly valve refers to a butterfly valve with two flanges. When installing, it is only necessary to match the flange holes on the flange butterfly valve with the flange holes on the pipeline one by one and connect them with bolts. Flange butterfly valves are suitable for large-diameter valves. As the diameter increases, the number of flange holes of the flange butterfly valve itself also increases accordingly, thereby providing better stability when connecting the pipeline.

There are obvious differences between flange butterfly valves and wafer butterfly valves.

1. Installation method

The flange butterfly valve is directly connected to the pipeline through its own flange, while the wafer butterfly valve needs to use two flanges to clamp it in the middle of the pipeline. Secondly, due to the difference in structural length and weight, flange butterfly valves are more suitable for large-diameter pipelines, while wafer butterfly valves are more suitable for small-diameter pipelines.

2. Scope of application

Both flange butterfly valves and wafer butterfly valves can be selected in two forms: hard seal and soft seal. Hard seal is suitable for high temperature and high pressure environment, while soft seal is suitable for normal temperature and low pressure pipeline system.

3. Application scenario

Wafer butterfly valves are usually suitable for low pressure and low medium temperature scenes, such as drinking water, neutral gas, etc.; while flange butterfly valves are suitable for higher pressure, more complex and high temperature media, usually used in petrochemical, metallurgy, power and other fields.

Selection suggestions

When choosing the butterfly valve connection method, factors such as the nature of the medium, working pressure and temperature, connection form, etc. need to be considered. For low pressure and neutral media, wafer butterfly valves can meet the requirements, and wafer butterfly valves with easy installation and low cost can be selected; for high pressure and complex media scenes, it is recommended to choose more reliable and longer service life flange butterfly valves.

As a commonly used control valve, butterfly valves have advantages and disadvantages in wafer and flange connection methods. When selecting, it is necessary to comprehensively consider factors such as the properties of the medium, working pressure and temperature, connection form, etc., and choose the appropriate connection method and model to ensure the safety and stability of the system.