| Face to Face: |

API609 |

| Test and Inspection: |

API598 |

| Top Flange Standard: |

ISO5211 |

| Epoxy Spraying: |

RAL 5005 or customized |

| Documents Service: |

FORM E Certificate of Origin/Certificate of Material/Pressure Testing Report |

| Working Temperature: |

-20℃~120℃ |

|

Nominal Pressure: |

PN10/PN16 |

|

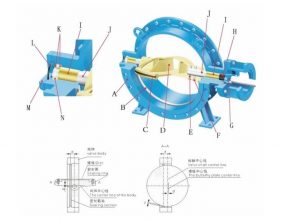

Double Eccentric Butterfly Valve |

|

| Body Material: |

Ductile Iron |

| Disc Material: |

Ductile iron |

| Shaft Material: |

2Cr13 |

| Seat Material: |

EPDM rubber |

The structure features that the valve stem axis deviates from the center of the disc and the center of the body.

The effect of double eccentricity enables the disc to be quickly removed from the seat after the valve is opened, greatly eliminating the unnecessary excessive extrusion and scratching phenomenon between the disc and the seat, reducing the opening resistance distance, reducing wear, and improving the life of the seat.

Greatly reduce the scraping, but also makes double eccentric butterfly valve can also use metal seat, improve the application of butterfly valve in the field of high temperature.

1.Double eccentric butterfly valve is more resistant to high pressure,longer life and good stability than the concentric butterfly valve.

2.With two-way sealing function, good sealing performance, positive and negative directions can reach "zero leakage". Installation is not limited by the flow of media.

3.Valve body, the main material of the butterfly plate are made of ductile iron, and the sealing pair is made of stainless steel and rubber, with a long service life.

4.Reasonable design,compact structure, easy assembly and disassembly and easy maintenance.

5.Eccentric structure,reduce the friction of the seal ring,prolong the service life of the valve.

6.Completely sealed, zero leakage. It can be used in ultra-high vacuum condition.

The double eccentric soft sealing butterfly valve solves the problem that the disc of the concentric sealing butterfly valve rubs the valve body sealing ring,causing damage to the sealing ring. The disc sealing ring leaves the valve seat at the moment the valve is opened and the sealing surface of the disc contacts the valve seat when the valve is closed a few degrees later,avoiding the phenomenon that the sealing surface is damaged due to consistent friction during the opening and closing process.

| DOUBLE ECCENTRIC BUTTERFLY VALVE | ||||||||||||||||

| Bidirectional Pressure Seal for Wafer & Flange End Connection | ||||||||||||||||

| DN | D1 | D2 | D3 | L | L1 | b | n-d | H1 | H2 | H4 | A1 | A2 | A3 | φ1 | φ2 | |

| Flange Type | Wafer Type | Steel | Ductile Iron | |||||||||||||

| 40 | 150 | 110 | 84 | 106 | 33 | 18 | 18 | 4-φ18 | 86 | 185 | 190 | 125 | 126 | 156 | 120 | 200 |

| 50 | 165 | 125 | 99 | 108 | 43 | 20 | 20 | 4-φ18 | 98 | 195 | 190 | 125 | 126 | 156 | 120 | 200 |

| 65 | 185 | 145 | 118 | 112 | 46 | 20 | 20 | 4-φ18 | 108 | 205 | 190 | 125 | 126 | 156 | 120 | 200 |

| 80 | 200 | 160 | 132 | 114 | 64 | 20 | 20 | 8-φ18 | 115 | 215 | 190 | 125 | 126 | 156 | 120 | 200 |

| 100 | 220 | 180 | 156 | 127 | 64 | 22 | 22 | 8-φ18 | 125 | 225 | 190 | 125 | 126 | 168 | 120 | 200 |

| 125 | 250 | 210 | 184 | 140 | 70 | 22 | 24 | 8-φ18 | 143 | 265 | 190 | 175 | 126 | 168 | 180 | 200 |

| 150 | 285 | 240 | 211 | 140 | 76 | 24 | 24 | 8-φ22 | 161 | 285 | 190 | 175 | 126 | 250 | 180 | 200 |

| 200 | 340 | 295 | 266 | 152 | 89 | 24 | 24 | 8-φ22 | 192 | 345 | 216 | 200 | 175 | 250 | 240 | 360 |

| 250 | 395 | 350 | 319 | 165 | 114 | 26 | 26 | 12-φ22 | 220 | 375 | 216 | 200 | 175 | 250 | 240 | 360 |

| 300 | 445 | 400 | 370 | 178 | 114 | 26 | 26 | 12-φ22 | 249 | 430 | 216 | 232 | 268 | 290 | 320 | 360 |

| 350 | 505 | 460 | 429 | 190 | 127 | 26 | 26 | 16-φ22 | 279 | 465 | 202 | 232 | 268 | 290 | 320 | 360 |

| 400 | 565 | 515 | 480 | 216 | 140 | 26 | 26 | 16-φ26 | 315 | 540 | 202 | 232 | 268 | 290 | 400 | 500 |

| 450 | 615 | 565 | 530 | 222 | 152 | 28 | 28 | 20-φ26 | 340 | 570 | 202 | 276 | 268 | 290 | 400 | 500 |

| 500 | 670 | 620 | 582 | 229 | 152 | 28 | 28 | 20-φ26 | 367 | 605 | 202 | 276 | 268 | 290 | 400 | 500 |

| 600 | 780 | 725 | 682 | 267 | 178 | 30 | 30 | 20-φ30 | 432 | 705 | 202 | 425 | 460 | 410 | 500 | 500 |

| 700 | 895 | 840 | 794 | 292 | 229 | 30 | 33 | 24-φ30 | 490 | 765 | 205 | 425 | 460 | 410 | 500 | 500 |

| 800 | 1015 | 950 | 901 | 318 | 241 | 32 | 35 | 24-φ33 | 555 | 870 | 205 | 480 | 610 | 305 | 600 | 300 |

| 900 | 1115 | 1050 | 1001 | 330 | 241 | 34 | 38 | 28-φ33 | 606 | 925 | 260 | 480 | 610 | 305 | 600 | 300 |

| 1000 | 1230 | 1160 | 1112 | 410 | 300 | 34 | 40 | 28-φ36 | 673 | 1035 | 260 | 525 | 650 | 385 | 600 | 400 |

| 1200 | 1455 | 1380 | 1328 | 470 | 360 | 38 | 45 | 32-φ39 | 786 | 1155 | 260 | 525 | 650 | 385 | 600 | 400 |

| 1400 | 1675 | 1590 | 1530 | 530 | 390 | 42 | 46 | 36-φ42 | 912 | 1350 | 260 | 705 | 745 | 535 | 720 | 500 |

| 1600 | 1915 | 1820 | 1750 | 600 | 440 | 46 | 49 | 40-φ48 | 1032 | 1457 | 260 | 705 | 745 | 535 | 720 | 500 |

| 1800 | 2115 | 2020 | 1950 | 670 | 490 | 50 | 52 | 44-φ48 | 1154 | 1670 | 260 | 850 | 820 | 660 | 720 | 610 |

| 2000 | 2325 | 2230 | 2150 | 760 | 540 | 54 | 55 | 44-φ48 | 1295 | 1780 | 260 | 850 | 820 | 660 | 720 | 610 |

It is mainly applicable to water plant, power plant, steel plant smelting, chemical industry, water source spring project, environmental facilities construction, steel plant smelting, air conditioning system, building system, chemical industry and other systems for drainage, especially applicable to the waterway pipeline, as a regulating and intercepting equipment.

Helping you with our 10 years experiences of valve products industry