| Face to Face: |

API609 |

| Test and Inspection: |

API598 |

| Top Flange Standard: |

ISO5211 |

| Epoxy Spraying: |

RAL 5005 or customized |

| Documents Service: |

FORM E Certificate of Origin/Certificate of Material/Pressure Testing Report |

| Working Temperature: |

-20℃~120℃ |

|

Nominal Pressure: |

PN10/PN16/CLASS125/CLASS150/10K/5K |

|

Available Material: |

|

| Body Material: |

Ductile Iron |

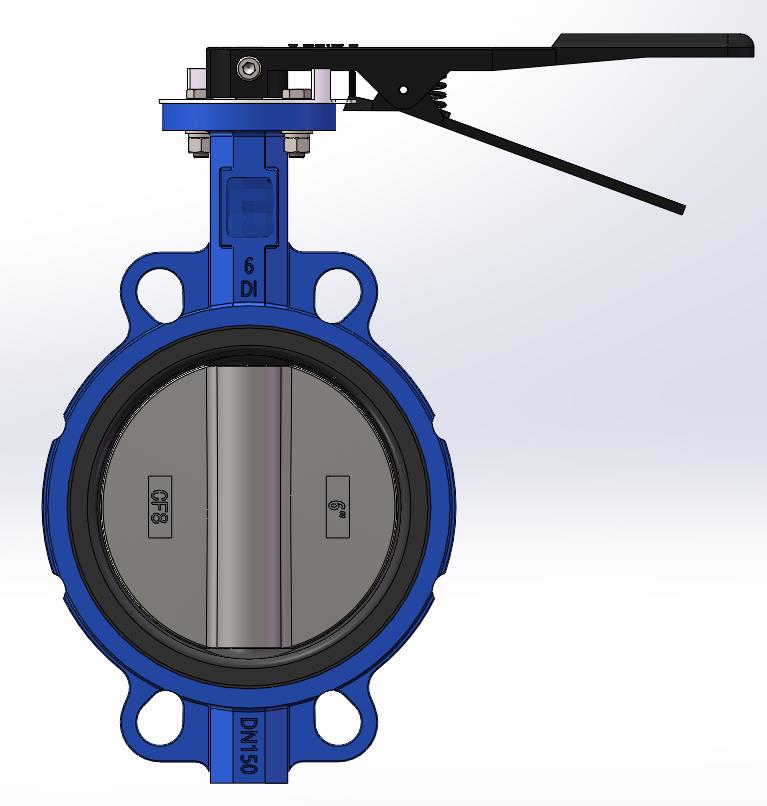

| Disc Material: |

Ductile iron/CF8/CF8M/CF3/CF3M/1.4529/AL.Bronze C954 or C958 |

| Shaft Material: |

SS416/SS420/SS304/SS316/SS431 |

| Seat Material: |

EPDM/NBR/Viton/PTFE |

|

Quality Standard: |

|

| Design & Manufacture Standard: |

API 609 |

| Face to Face Dimension Standard: |

API 609 |

| Test & Inspection Standard: |

API 598 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

B |

φD2 |

φD3 |

n-φd |

|

|

1.5″ |

DN40 |

33 |

69 |

65 |

127 |

25 |

9 |

65 |

50 |

4-8 |

|

2″ |

DN50 |

42 |

73.3 |

75 |

129 |

25 |

9 |

65 |

50 |

4-8 |

|

2.5″ |

DN65 |

44 |

86 |

82 |

136 |

25 |

9 |

65 |

50 |

4-8 |

|

3″ |

DN80 |

45 |

100.9 |

99 |

153 |

25 |

9 |

65 |

50 |

4-8 |

|

4″ |

DN100 |

51.5 |

132 |

110 |

167 |

28 |

11 |

90 |

70 |

4-10 |

|

5″ |

DN125 |

54 |

156 |

125 |

193 |

28 |

14 |

90 |

70 |

4-10 |

|

6″ |

DN150 |

55 |

185 |

145 |

209 |

28 |

14 |

90 |

70 |

4-10 |

|

8″ |

DN200 |

59 |

235 |

170 |

251 |

33 |

17 |

125 |

102 |

4-12 |

|

10″ |

DN250 |

66 |

289 |

210 |

280 |

33 |

22 |

125 |

102 |

4-12 |

|

12″ |

DN300 |

76 |

341 |

240 |

312 |

33 |

22 |

125 |

102 |

4-12 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

φd |

φD2 |

φD3 |

n-φd1 |

N-b |

K |

|

|

16″ |

DN400 |

86.5 |

436 |

320 |

403 |

52 |

33.15 |

175 |

140 |

4-18 |

1-10 |

36.2 |

|

18″ |

DN450 |

104.6 |

487 |

351 |

415 |

52 |

38 |

175 |

140 |

4-18 |

1-10 |

41 |

|

20″ |

DN500 |

130 |

532 |

386 |

466 |

64 |

41.15 |

175 |

140 |

4-18 |

1-12 |

44.2 |

|

24″ |

DN600 |

152 |

651 |

446 |

525 |

70 |

50.65 |

210 |

165 |

4-22 |

1-16 |

54.7 |

|

28″ |

DN700 |

163 |

741 |

520 |

618 |

95 |

63.35 |

300 |

254 |

8-18 |

2-18 |

71.4 |

|

32″ |

DN800 |

188 |

847 |

580 |

665 |

95 |

63.35 |

300 |

254 |

8-18 |

2-18 |

71.4 |

|

36″ |

DN900 |

203 |

971 |

670 |

720 |

130 |

75 |

300 |

254 |

8-18 |

2-20 |

84 |

|

40″ |

DN1000 |

216 |

1050 |

735 |

800 |

130 |

85 |

300 |

254 |

8-18 |

2-22 |

95 |

|

48″ |

DN1200 |

276 |

1261 |

878 |

940 |

150 |

105 |

350 |

298 |

8-22 |

2-28 |

117 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

B |

φD2 |

φD3 |

n-φd |

φD4 |

|

|

1.5″ |

DN40 |

33 |

69 |

65 |

127 |

14 |

9 |

65 |

50 |

4-8 |

135 |

|

2″ |

DN50 |

42 |

73.3 |

75 |

129 |

14 |

9 |

65 |

50 |

4-8 |

135 |

|

2.5″ |

DN65 |

44 |

86 |

82 |

136 |

18 |

9 |

65 |

50 |

4-8 |

135 |

|

3″ |

DN80 |

45 |

100.9 |

99 |

153 |

18 |

9 |

65 |

50 |

4-8 |

135 |

|

4″ |

DN100 |

51.5 |

132 |

110 |

167 |

20 |

11 |

90 |

70 |

4-10 |

135 |

|

5″ |

DN125 |

54 |

156 |

125 |

193 |

20 |

14 |

90 |

70 |

4-10 |

135 |

|

6″ |

DN150 |

55 |

185 |

145 |

209 |

25 |

14 |

90 |

70 |

4-10 |

135 |

|

8″ |

DN200 |

59 |

235 |

170 |

251 |

25 |

17 |

125 |

102 |

4-12 |

270 |

|

10″ |

DN250 |

66 |

289 |

210 |

280 |

30 |

22 |

125 |

102 |

4-12 |

270 |

|

12″ |

DN300 |

76 |

341 |

240 |

312 |

30 |

22 |

125 |

102 |

4-12 |

270 |

|

14″ |

DN350 |

76 |

372 |

271 |

327 |

40 |

22 |

125 |

102 |

4-12 |

270 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

B |

φD2 |

φD3 |

n-φd |

φD4 |

|

|

1.5″ |

DN40 |

33 |

69 |

65 |

127 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

2″ |

DN50 |

42 |

73.3 |

75 |

129 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

2.5″ |

DN65 |

44 |

86 |

82 |

136 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

3″ |

DN80 |

45 |

100.9 |

99 |

153 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

4″ |

DN100 |

51.5 |

132 |

110 |

167 |

28 |

11 |

90 |

70 |

4-10 |

135 |

|

5″ |

DN125 |

54 |

156 |

125 |

193 |

28 |

14 |

90 |

70 |

4-10 |

135 |

|

6″ |

DN150 |

55 |

185 |

145 |

209 |

28 |

14 |

90 |

70 |

4-10 |

135 |

|

8″ |

DN200 |

59 |

235 |

170 |

251 |

33 |

17 |

125 |

102 |

4-12 |

270 |

|

10″ |

DN250 |

66 |

289 |

210 |

280 |

33 |

22 |

125 |

102 |

4-12 |

270 |

|

12″ |

DN300 |

76 |

341 |

240 |

312 |

33 |

22 |

125 |

102 |

4-12 |

270 |

|

14″ |

DN350 |

76 |

372 |

271 |

327 |

45 |

22 |

125 |

102 |

4-12 |

270 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

φd |

φD2 |

φD3 |

n-φd1 |

N-b |

K |

|

|

16″ |

DN400 |

86.5 |

436 |

320 |

403 |

52 |

33.15 |

175 |

140 |

4-18 |

1-10 |

36.2 |

|

18″ |

DN450 |

104.6 |

487 |

351 |

415 |

52 |

38 |

175 |

140 |

4-18 |

1-10 |

41 |

|

20″ |

DN500 |

130 |

532 |

386 |

466 |

64 |

41.15 |

175 |

140 |

4-18 |

1-12 |

44.2 |

|

24″ |

DN600 |

152 |

651 |

446 |

525 |

70 |

50.65 |

210 |

165 |

4-22 |

1-16 |

54.7 |

|

28″ |

DN700 |

163 |

741 |

520 |

618 |

95 |

63.35 |

300 |

254 |

8-18 |

2-18 |

71.4 |

|

32″ |

DN800 |

188 |

847 |

580 |

665 |

95 |

63.35 |

300 |

254 |

8-18 |

2-18 |

71.4 |

|

36″ |

DN900 |

203 |

971 |

670 |

720 |

130 |

75 |

300 |

254 |

8-18 |

2-20 |

84 |

|

40″ |

DN1000 |

216 |

1050 |

735 |

800 |

130 |

85 |

300 |

254 |

8-18 |

2-22 |

95 |

|

48″ |

DN1200 |

276 |

1261 |

878 |

940 |

150 |

105 |

350 |

298 |

8-22 |

2-28 |

117 |

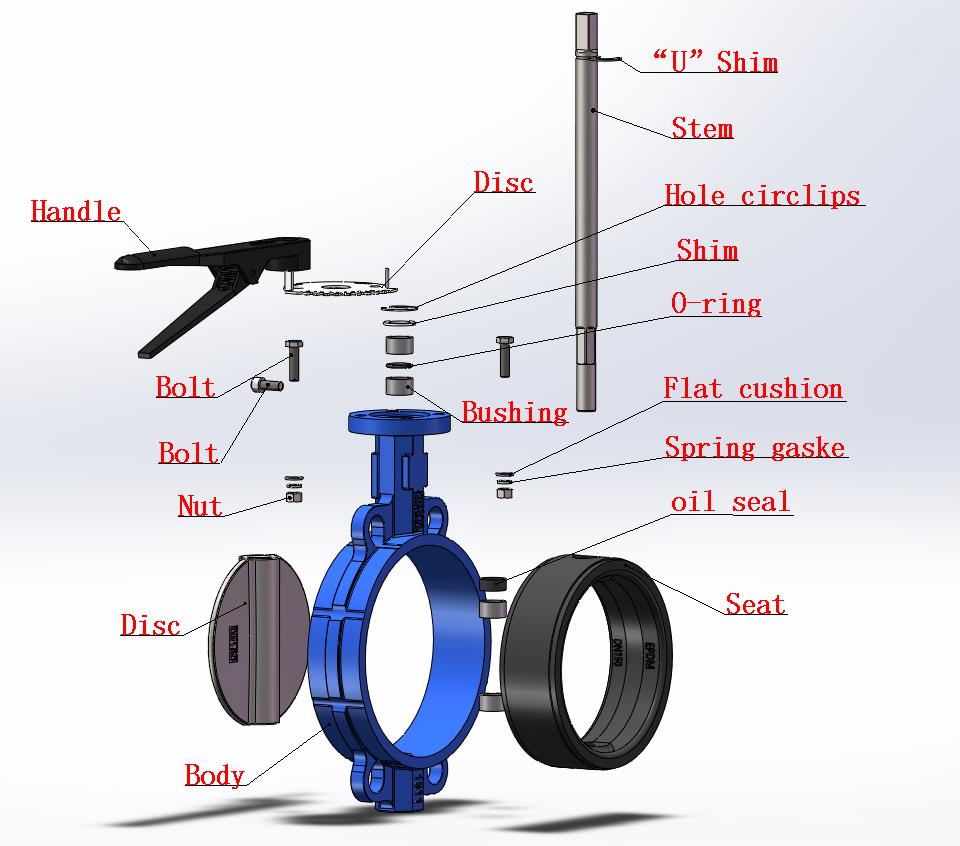

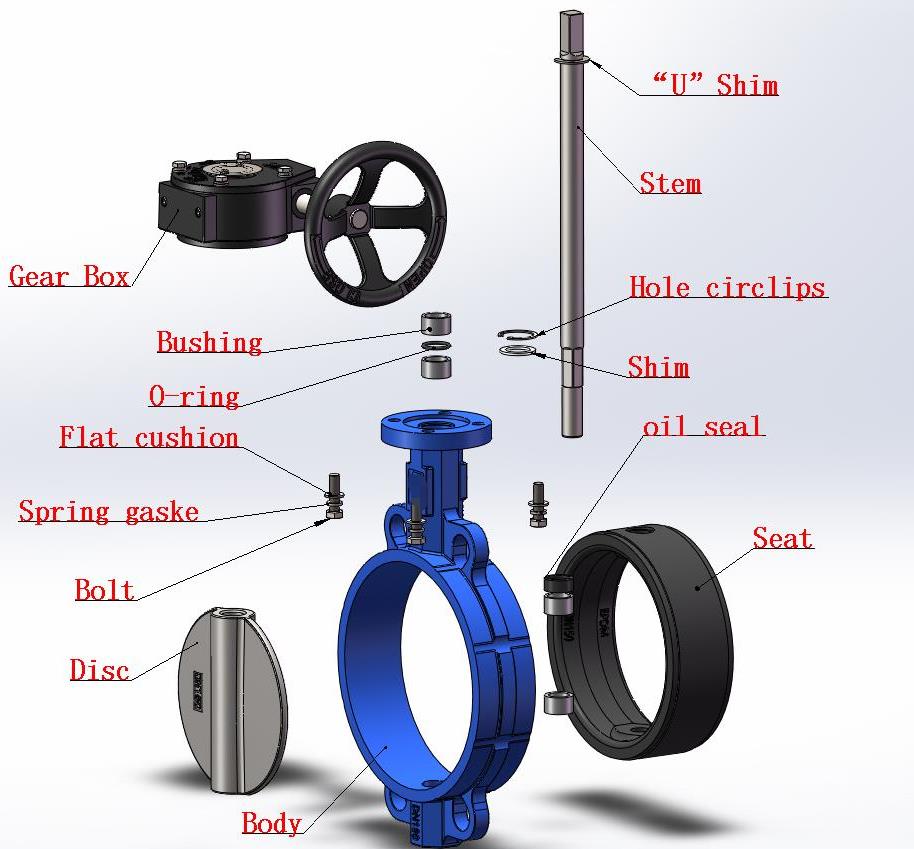

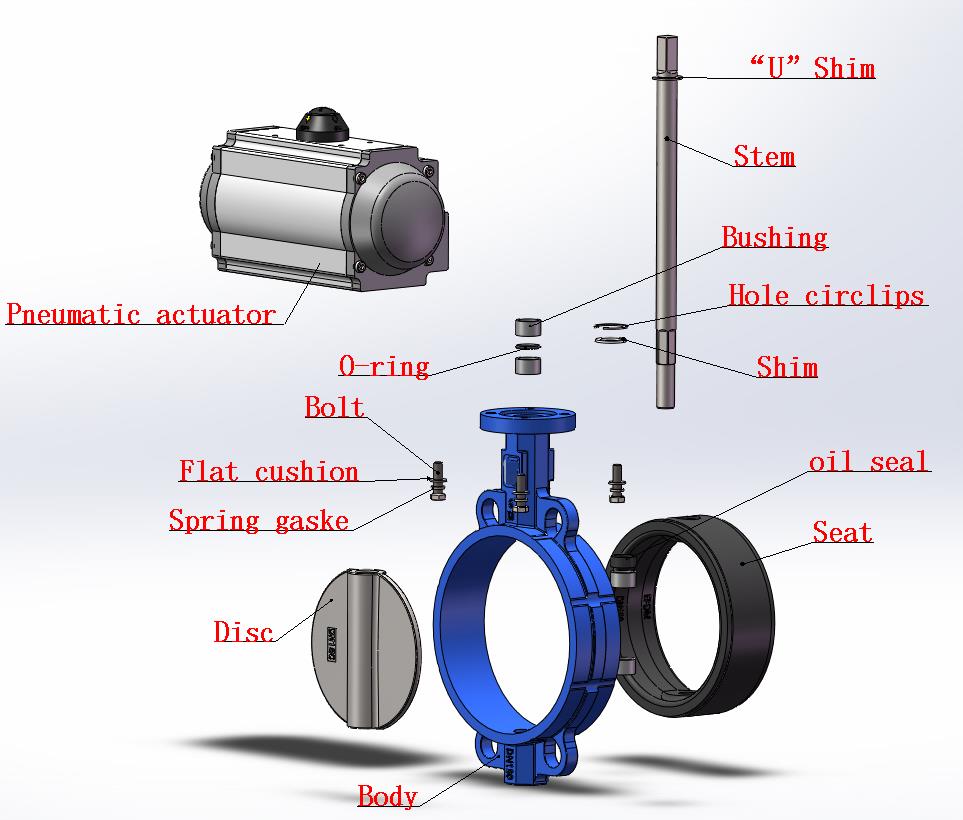

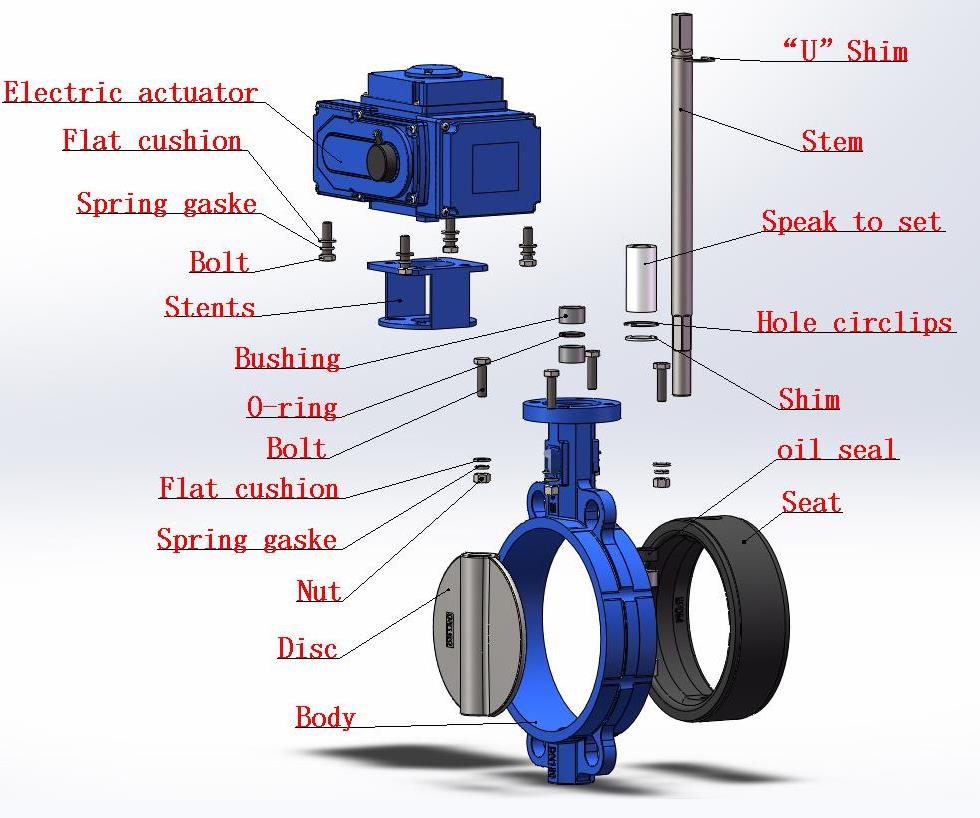

1.High performance seat rubber(50% rubber content).

2.EPDM soft seated which can be replaced when demaged.

3.Valve switch life-time is more than 30000 times.

4.Axial seal(O-ring+oil seal,double seal structure).

5.Adopt epoxy spraying(stronger adhesion and good weather resistance).

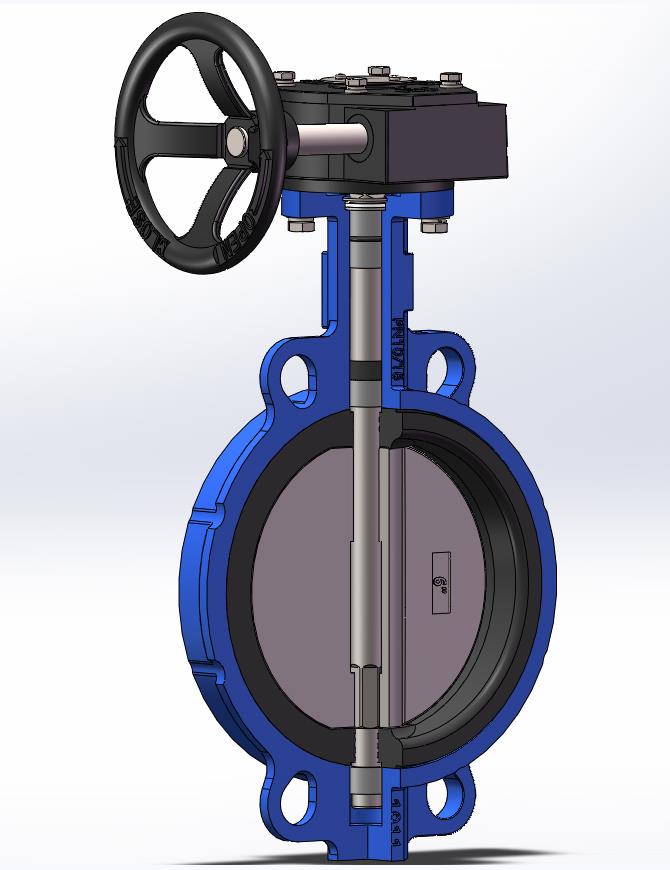

6.Ductile Iron Lever&Worm Gear(stronger corrosion resistance).

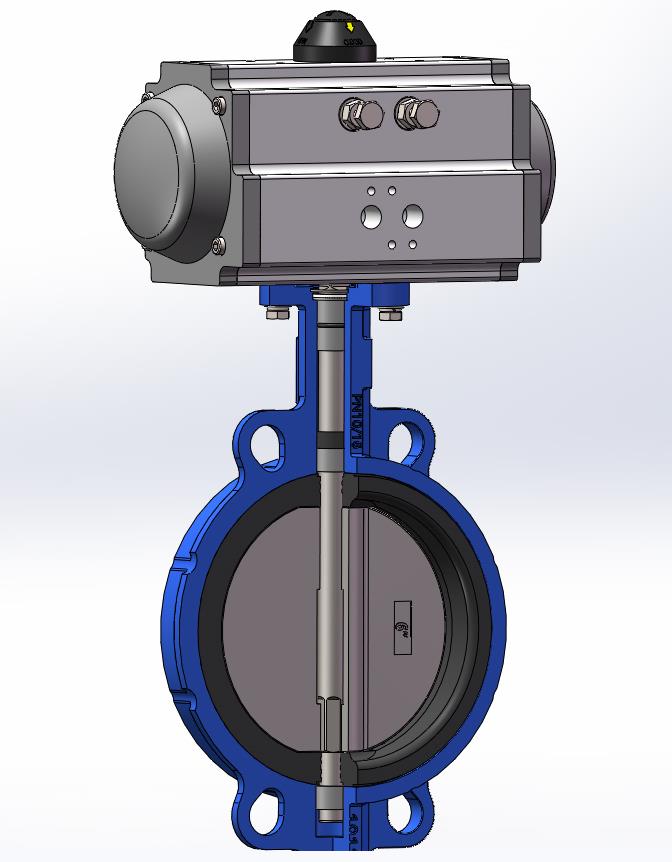

7.Pneumatic Actuator adopts double piston rack structure.

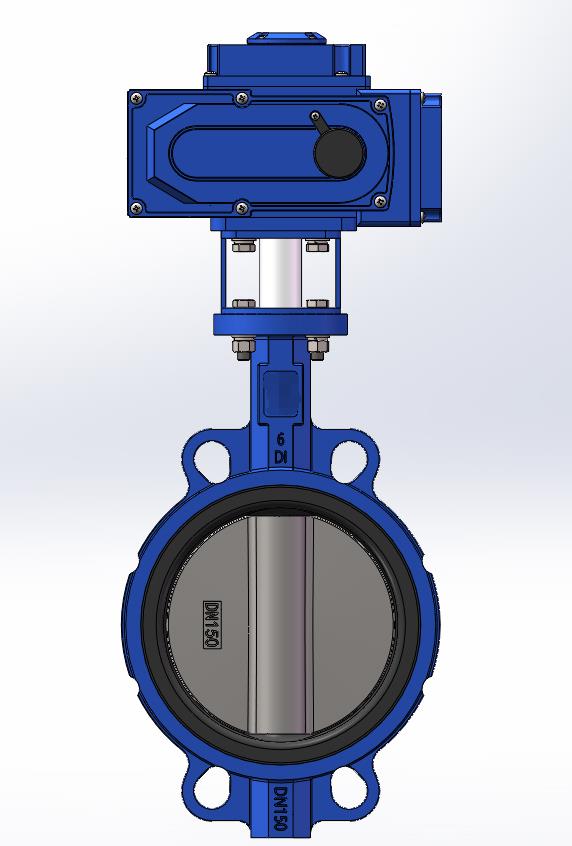

8.Electric Actuator supplying voltage: 380V,220V or customized.

9.Pressure Testing Report,Certificate of Material and FORM E Certificate Of Origin can be provided.

Water treatment, HVAC, Urban construction, Petroleum, Chemical Indsutry, Textile & Papermaking

Helping you with our 10 years experiences of valve products industry