| Face to Face Length: |

API609 |

| Test and Inspection: |

API598 |

| Top Flange Standard: |

ISO5211 |

| Flange Size Standard: |

ASME B16.5;ASME B16.47;ASME B16.1;DIN2501 |

| Documents Service: |

FORM E Certificate of Origin/Certificate of Material/Pressure Testing Report |

| Working Temperature: |

-20℃~120℃ |

| Nominal Pressure: |

PN10/PN16/CLASS150 |

| Available Voltage: |

380V 3-phase/AC220V or customized |

|

Available Material: |

|

| Body Material: |

Ductile Iron |

| Disc Material: |

Ductile iron /CF8/CF8M/CF3/CF3M/1.4529/AL.BRONZE C.954 or C958 |

| Shaft Material: |

45 Steel/SS416/SS420/SS304/SS316/SS431 |

| Seat Material: |

EPDM/NBR/Viton/PTFE |

| Epoxy coating |

RAL5005 or customized |

|

Quality Standard: |

|

| Design & Manufacture Standard: |

API 609 |

| Face to Face Dimension Standard: |

API 609 |

| Test & Inspection Standard: |

API 598 |

| Top Flange Connection Standard: |

ISO 5211 |

| Flange Size Standard: |

ASME B16.5/ASME B16.47/ASME B16.1/JIS B2220/DIN 2501 |

|

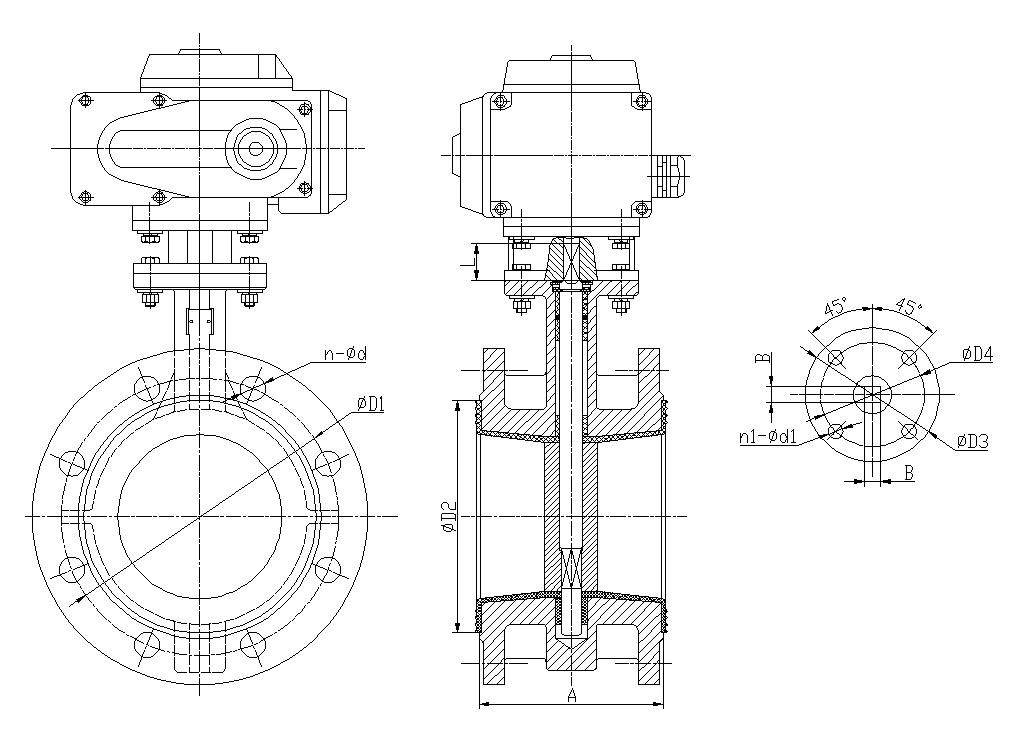

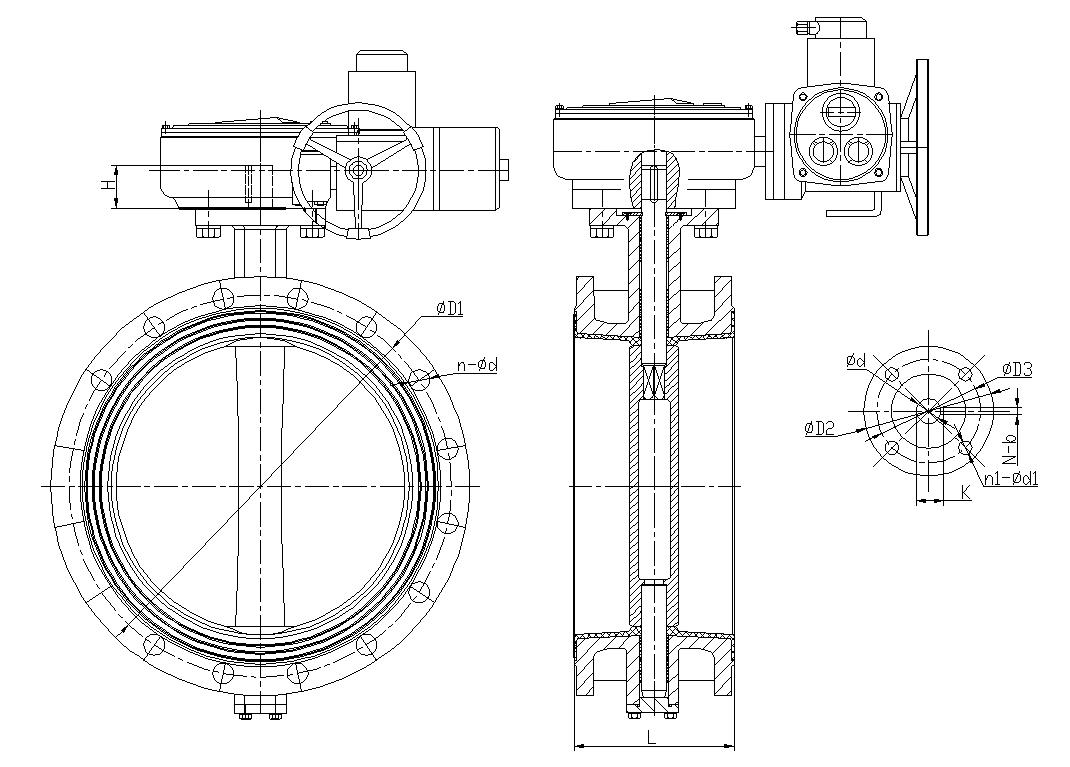

DN |

A |

PN16 |

PN10 |

150LB |

D2 |

L |

B |

φD3 |

φD4 |

n1-φd1 |

φD5 |

||||

|

D1 |

n-φd |

D1 |

n-φd |

D1 |

n-φd |

||||||||||

|

2″ |

DN50 |

108 |

125 |

4-19 |

125 |

4-19 |

120.7 |

4-19 |

90 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

2.5″ |

DN65 |

112 |

145 |

4-19 |

145 |

4-19 |

139.7 |

4-19 |

110 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

3″ |

DN80 |

114 |

160 |

8-19 |

160 |

8-19 |

152.4 |

4-19 |

124 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

4″ |

DN100 |

127 |

180 |

8-19 |

180 |

8-19 |

190.5 |

8-19 |

150 |

28 |

11 |

90 |

70 |

4-10 |

135 |

|

5″ |

DN125 |

140 |

210 |

8-19 |

210 |

8-19 |

215.9 |

8-22.4 |

176 |

28 |

14 |

90 |

70 |

4-10 |

135 |

|

6″ |

DN150 |

140 |

240 |

8-23 |

240 |

8-23 |

241.3 |

8-22.4 |

200 |

28 |

14 |

90 |

70 |

4-10 |

135 |

|

8″ |

DN200 |

152 |

295 |

12-23 |

295 |

8-23 |

298.5 |

8-22.4 |

258 |

33 |

17 |

125 |

102 |

4-12 |

270 |

|

10″ |

DN250 |

165 |

355 |

12-28 |

350 |

12-23 |

362 |

12-25.4 |

310 |

33 |

22 |

125 |

102 |

4-12 |

270 |

|

12″ |

DN300 |

178 |

410 |

12-28 |

400 |

12-23 |

431.8 |

12-25.4 |

362 |

33 |

22 |

125 |

102 |

4-12 |

270 |

|

14″ |

DN350 |

190 |

470 |

16-28 |

460 |

16-23 |

476.3 |

12-28.4 |

421 |

45 |

22 |

125 |

102 |

4-12 |

270 |

|

DN |

L |

PN16 |

PN10 |

150LB |

H |

φd |

K |

φD2 |

φD3 |

n1-φd1 |

N-b |

||||

|

|

|

D1 |

n-φd |

D1 |

n-φd |

D1 |

n-φd |

|

|

|

|

|

|

|

|

|

16″ |

DN400 |

216 |

525 |

16-31 |

515 |

16-28 |

539.8 |

16-28.4 |

52 |

33.15 |

36.2 |

175 |

140 |

4-18 |

1-10 |

|

18″ |

DN450 |

222 |

585 |

20-31 |

565 |

20-28 |

577.9 |

16-31.8 |

52 |

38 |

41 |

175 |

140 |

4-18 |

1-10 |

|

20″ |

DN500 |

229 |

650 |

20-34 |

620 |

20-28 |

635 |

20-31.8 |

64 |

41.15 |

44.2 |

175 |

140 |

4-18 |

1-12 |

|

24″ |

DN600 |

267 |

770 |

20-37 |

725 |

20-31 |

749.3 |

20-35.1 |

70 |

50.65 |

54.7 |

210 |

165 |

4-22 |

1-16 |

|

28″ |

DN700 |

292 |

840 |

24-37 |

840 |

24-31 |

863.6 |

28-35.1 |

95 |

63.35 |

71.4 |

300 |

254 |

8-18 |

2-18 |

|

32″ |

DN800 |

318 |

950 |

24-40 |

950 |

24-34 |

977.9 |

28-41.1 |

95 |

63.35 |

71.4 |

300 |

254 |

8-18 |

2-18 |

|

36″ |

DN900 |

330 |

1050 |

28-40 |

1050 |

28-34 |

1085.8 |

32-41.1 |

130 |

75 |

84 |

300 |

254 |

8-18 |

2-20 |

|

40″ |

DN1000 |

410 |

1170 |

28-43 |

1160 |

28-37 |

1200.2 |

36-41.1 |

130 |

85 |

95 |

300 |

254 |

8-18 |

2-22 |

|

48″ |

DN1200 |

470 |

1390 |

32-49 |

1380 |

32-40 |

1422.4 |

44-41.1 |

150 |

105 |

117 |

350 |

298 |

8-22 |

2-28 |

|

56″ |

DN1400 |

530 |

1590 |

36-49 |

1590 |

36-44 |

1651 |

48-47.8 |

200 |

120 |

134 |

415 |

356 |

8-33 |

2-32 |

|

60″ |

DN1500 |

570 |

1710 |

36-57 |

1700 |

36-44 |

1759 |

52-47.8 |

200 |

140 |

156 |

415 |

356 |

8-33 |

2-36 |

|

64″ |

DN1600 |

600 |

1820 |

40-56 |

1820 |

40-50 |

-- |

-- |

200 |

140 |

156 |

415 |

365 |

8-33 |

2-36 |

|

72″ |

DN1800 |

670 |

2020 |

44-56 |

2020 |

44-50 |

2096 |

60-50.8 |

280 |

160 |

178 |

475 |

406 |

8-40 |

2-40 |

|

80″ |

DN2000 |

760 |

2230 |

48-62 |

2230 |

48-50 |

-- |

-- |

280 |

160 |

178 |

475 |

406 |

8-40 |

2-40 |

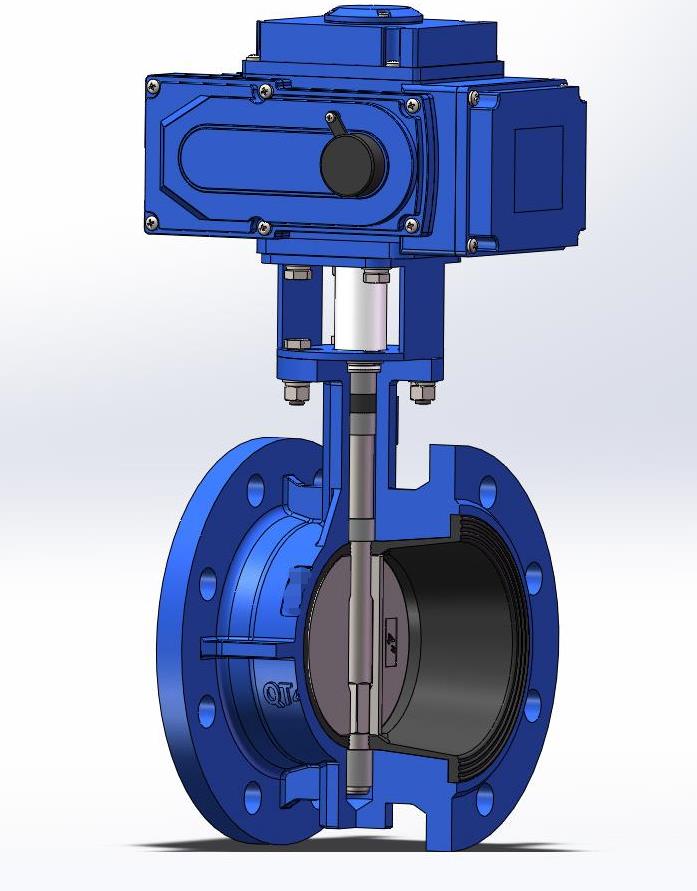

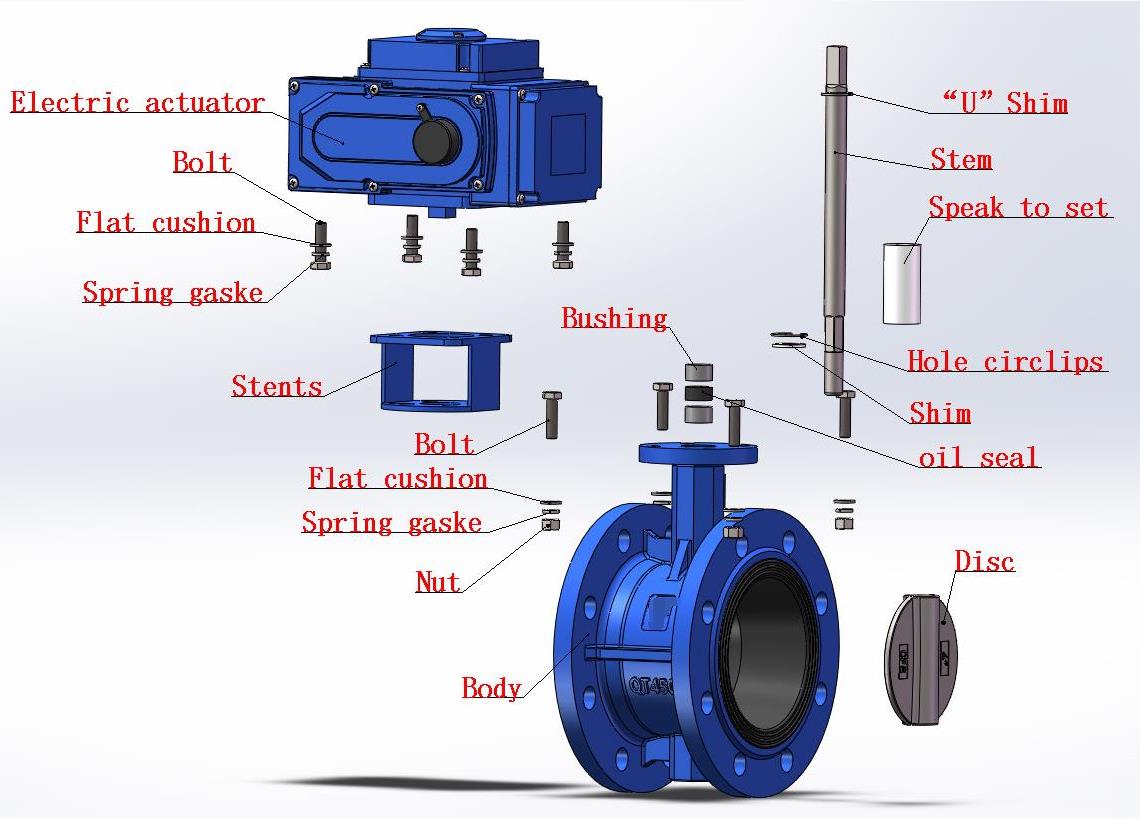

1.The structure is simple and compact,the rotation of 90 °is quickly to open and close.

2.All products can provide the pressure test report & Certificate of material.

3.High performance seat rubber: The rubber content is 50% and the switch life is more than 30000 times.

4.The rubber and valve body are joined by vulcanization process and the joint is tight and doesn’t fall off

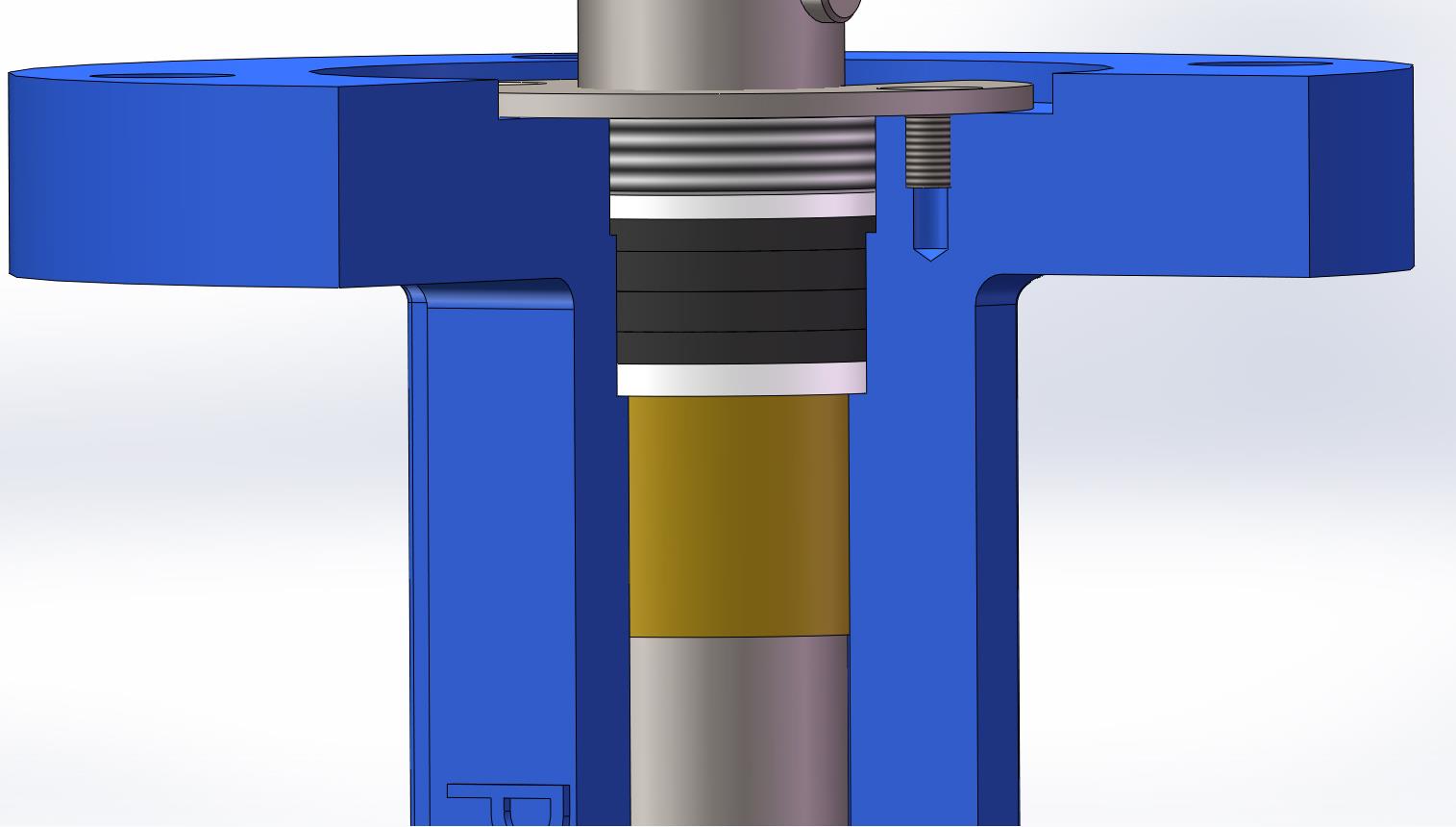

5.Axial seal: The valve shaft has a double seal structure design of oil seal and O-ring,smaller torque and reliable seal.The upper and lower shaft holes of DN350 and above large diameter valves are designed with packing box structure and the packing is pressed by the gland to realize sealing.

6.Surface coating:Epoxy powder coating is adopted which is strong adhesion and good weather resistance. It can be used indoors and outdoors.

Water treatment, HVAC, Urban construction, Petroleum, Chemical Indsutry, Textile & Papermaking

Helping you with our 10 years experiences of valve products industry