| Working Pressure: |

0.6Mpa~2.5MPa |

| Nominal Size: |

DN32-DN4000 |

| Working temperature: |

-20℃~+115℃ |

| Working Medium: |

Weak acid, weak alkali, weak corrosion, oil, hot water, cold water, etc. |

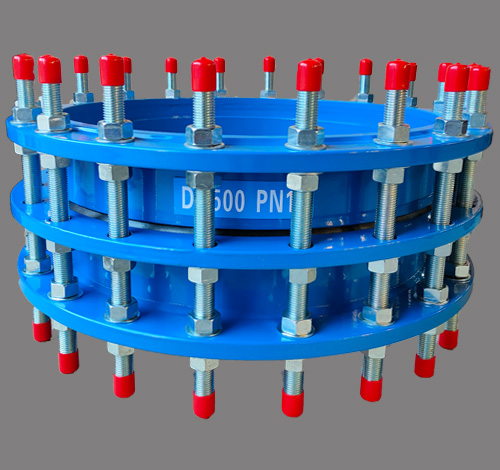

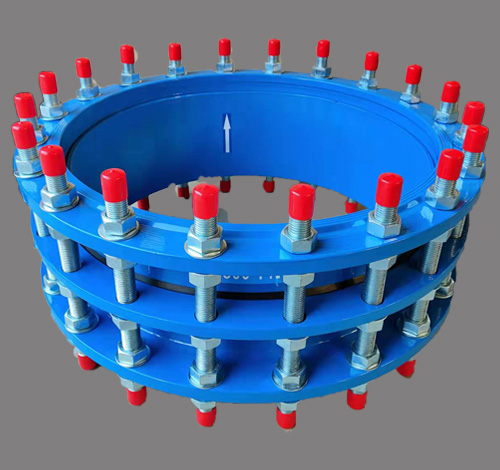

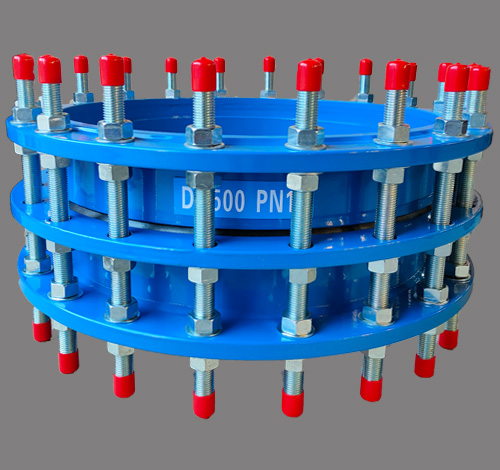

| Available Material: |

Ductile iron, Carbon steel, Stainless Steel |

| Product Surface: |

Epoxy spraying coating |

| Material Information: | |

|

Outer Tube |

Carbon Steel |

|

Seal Ring |

EPDM |

|

Gland Material: |

Ductile Iron,Carbon Steel |

| Bolts&Nuts Material |

Carbon Steel |

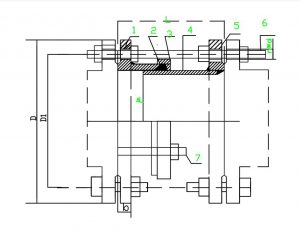

This power transmission joint can be detachable, it is composed of loose sleeve expansion joints, short pipe flanges, force transmission screws and other components.

It can transmit the pressure thrust (blind plate force) of the connected parts and compensate for pipeline errors, and has a certain The amount of adjustment is convenient for

adjustment in the actual construction environment.

1.Simple and convenient installation which is conducive to the disassembly and maintenance of pump valves.

2.This product is suitable for pipelines with flange connections on both sides, which is very convenient for installation and maintenance,also itcan be adjusted according to the

size of the site.

3.When working, the axial thrust can be transmitted to the whole pipeline.

4.It can reverse the axial thrust of the pipeline to the whole pipeline to avoid local pressure.

| DN | Outer Diameter (mm) |

L | Flange Connecting Dimension | |||||||

| 0.6Mpa | 1.0Mpa | |||||||||

| mm | D | D1 | N-φD | b | D | D1 | N-φD | b | ||

| 65 | 76 | 200 | 160 | 130 | 4-M12 | 16 | 185 | 145 | 4-M16 | 20 |

| 80 | 89 | 190 | 150 | 4-M16 | 18 | 200 | 160 | 8-M16 | 22 | |

| 100 | 114 | 210 | 170 | 220 | 180 | 24 | ||||

| 125 | 140 | 240 | 200 | 8-M16 | 20 | 250 | 210 | 26 | ||

| 150 | 168 | 265 | 225 | 285 | 240 | 8-M20 | ||||

| 200 | 219 | 320 | 280 | 22 | 340 | 295 | 28 | |||

| 250 | 273 | 375 | 335 | 12-M16 | 24 | 395 | 350 | 12-M20 | ||

| 300 | 325 | 220 | 440 | 395 | 12-M20 | 24 | 445 | 400 | 12-M20 | 28 |

| 350 | 377 | 490 | 445 | 26 | 505 | 460 | 16-M20 | 30 | ||

| 400 | 426 | 540 | 495 | 16-M20 | 28 | 565 | 515 | 16-M24 | 32 | |

| 450 | 480 | 595 | 550 | 28 | 615 | 565 | 20-M24 | 32 | ||

| 530 | 530 | 645 | 600 | 20-M20 | 30 | 670 | 620 | 34 | ||

| 600 | 630 | 240 | 755 | 705 | 20-M24 | 30 | 780 | 725 | 20-M27 | 36 |

| 700 | 720 | 860 | 810 | 24-M24 | 32 | 895 | 840 | 24-M27 | 40 | |

| 800 | 820 | 350 | 975 | 920 | 24-M27 | 34 | 1015 | 950 | 24-M30 | 44 |

| 900 | 920 | 1075 | 1020 | 24-M27 | 36 | 1115 | 1050 | 28-M30 | 46 | |

| 1000 | 1020 | 1175 | 1120 | 28-M27 | 36 | 1230 | 1160 | 28-M33 | 50 | |

| 1200 | 1220 | 370 | 1405 | 1340 | 32-M30 | 40 | 1455 | 1380 | 32-M36 | 56 |

| 1400 | 1420 | 1630 | 1560 | 36-M33 | 44 | 1675 | 1590 | 36-M39 | 62 | |

Water treatment, HVAC, Urban construction, Petroleum, Chemical Indsutry, Textile & Papermaking

Helping you with our 10 years experiences of valve products industry