| Working Pressure: |

0.6Mpa~1.6MPa |

| Nominal Size: |

DN50-DN3600 |

| Working temperature: |

-20℃~+115℃ |

| Working Medium: |

Weak acid, weak alkali, weak corrosion, oil, hot water, cold water, etc. |

| Available Material: |

Ductile iron, Carbon steel, Stainless Steel |

| Product Surface: |

Epoxy spraying coating |

|

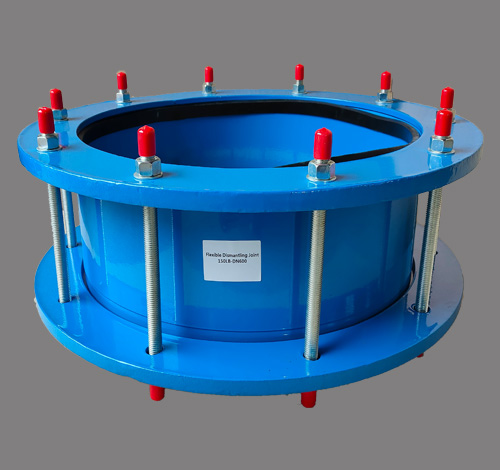

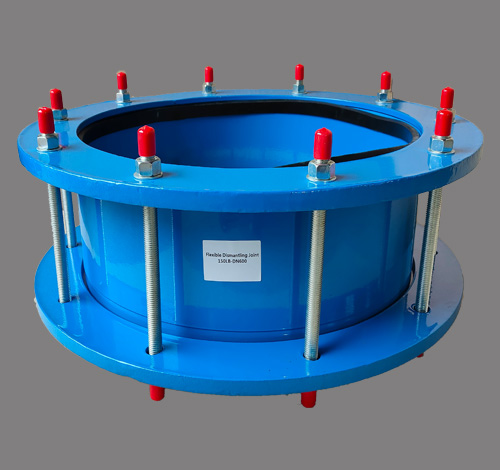

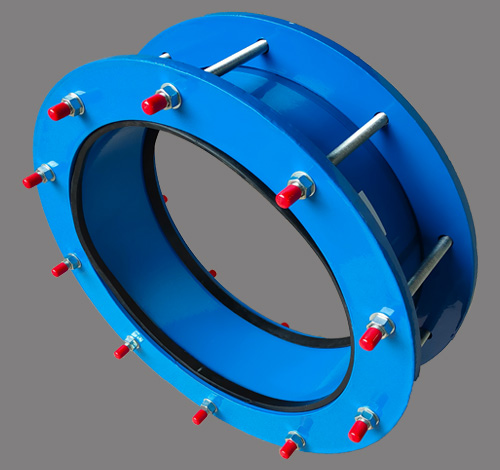

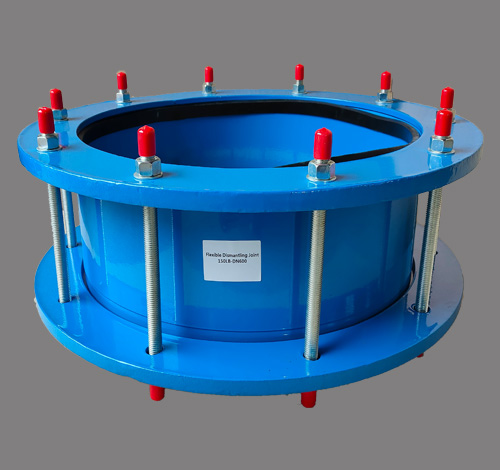

Flange Expansion Joint

|

|

|

Body Material: |

Ductile Iron,Carbon Steel |

|

Sealing Material: |

NBR,EPDM,Natural Rubber |

|

Gland Material: |

Ductile Iron,Carbon Steel |

| Bolts&Nuts Material |

Carbon Steel |

Product Introduction:

The expansion joint is composed of the body, the sealing ring, the gland and the expansion short tube.

On the basis of the original performance of the loose sleeve expansion joint, a limit device is added, and a double nut is used to lock at the expansion amount.

The double-flange limit expansion joint is suitable for connecting with flanges on both sides.

When installing, adjust the connection length at both ends of the product,tighten the gland bolts evenly in diagonal order, and then adjust the limit nuts, so that the pipe can be freely expanded and locked. The amount of expansion and contraction ensures the operation of the pipeline.

Product Features:

1.It is suitable for connecting the medium for conveying water, oil, gas and granular powder.

2. Large expansion capacity,simple and convenient installation, long service life (up to 10-30 years), and convenient maintenance.

3. The expander can compensate the axial expansion and contraction displacement of the pipeline due to the influence of thermal stress and mechanical vibration.

4. During the installation, it can compensate the butt joint problem of the pipeline due to the error in the actual construction process, thereby greatly reducing the construction difficulty and speeding up the construction progress.

5. Good expansion and contraction performance, long service life, easy to use, can greatly alleviate the adverse effects of the axial thrust of the pipeline.

6. It can effectively eliminate the adverse effects of ground subsidence or crustal changes on pipelines.

Installation Notes:

1. During installation, all moving parts should be kept able to realize effective activities.

2. A guide bracket should be installed during installation,because the vibration formed by the pipeline under the action of thermal stress and mechanical vibration is irregular, it is necessary to install the corresponding guide bracket so that the vibration of the pipeline is consistent with that of the expansion joint. The displacement compensation is consistent, so as to protect the service life of the pipeline.

3. During the installation process, the bolts should be gradually tightened under symmetrical pressure to prevent local leakage.

4. Regular maintenance should be carried out during use to reduce the probability of hidden dangers.

| DN |

Outer Diameter

|

Surface Dimension | n*d | ||||

| D1 | D2 | D | L | L1 | 0.6-1.6MPa | 2.5MPa | |

| 65 | 76 | 76 | 155 | 645 | 180 | 2-M12 | 2-M12 |

| 80 | 89 | 89 | 165 | ||||

| 100 | 108 | 108 | 195 | 2-M16 | |||

| 114 | 114 | 195 | |||||

| 125 | 133 | 133 | 225 | ||||

| 140 | 140 | 225 | |||||

| 150 | 159 | 159 | 255 | 2-M16 | 3-M16 | ||

| 168 | 168 | 255 | |||||

| 200 | 219 | 219 | 310 | ||||

| 250 | 273 | 273 | 375 | 3-M20 | 4-M20 | ||

| 300 | 325 | 325 | 440 | 655 | 220 | 5-M20 | |

| 350 | 377 | 377 | 490 | 4-M20 | |||

| 400 | 426 | 426 | 540 | ||||

| 450 | 480 | 480 | 590 | 5-M20 | 6-M20 | ||

| 500 | 530 | 530 | 645 | ||||

| 600 | 630 | 630 | 750 | ||||

| 700 | 720 | 720 | 850 | 6-M20 | 7-M20 | ||

| 800 | 820 | 820 | 965 | 1075 | 290 | 6-M24 | 8-M24 |

| 900 | 920 | 920 | 1065 | 7-M24 | 9-M24 | ||

| 1000 | 1020 | 1020 | 1165 | ||||

| 1200 | 1220 | 1220 | 1365 | 8-M24 | 10-M24 | ||

| 1400 | 1420 | 1428 | 1590 | 9-M27 | 12-M27 | ||

| 1500 | 1520 | 1528 | 1690 | ||||

| 1600 | 1620 | 1628 | 1795 | 10-M27 | 14-M27 | ||

| 1800 | 1820 | 1828 | 2000 | 11-M27 | 15-M30 | ||

| 2000 | 2020 | 2030 | 2200 | 12-M27 | 16-M30 | ||

| 2200 | 2220 | 2230 | 2420 | 13-M27 | |||

| 2400 | 2420 | 2430 | 2635 | 14-M30 | |||

| 2600 | 2620 | 2630 | 2835 | 15-M30 | |||

| 2800 | 2820 | 2830 | 3040 | 16-M33 | |||

| 3000 | 3020 | 3030 | 3240 | 17-M33 | |||

| 3200 | 3220 | 3230 | 3440 | 1130 | 400 | 18-M33 | |

| 3400 | 3420 | 3430 | 3640 | 19-M33 | |||

| 3600 | 3620 | 3630 | 3860 | 20-M33 | |||

| 3800 | 3820 | 3830 | 4080 | 20-M36 | |||

| 4000 | 4020 | 4030 | 4300 | 21-M36 | |||

Water treatment, HVAC, Urban construction, Petroleum, Chemical Indsutry, Textile & Papermaking

Helping you with our 10 years experiences of valve products industry