| Design Standard | API609/ASME B16.34 |

| Pressure Range | PN10/PN16/PN25/PN40/ANSI CLASS150/CLASS300/10K |

| Working Condition | High temperature,high frequency,strong corrosion |

| Temperature Range | -29℃+ 500℃ |

| Leakage Class | Zero leakage |

| End Connection | Wafer,Lug,Flange |

| Size Range | 2″-60″ |

Product Introduction:

High performance butterfly valve commonly used in gas and vacuum industries with high switching frequencies, the service life can reach millions of times. Even if the valve seat is damaged, it can be replaced on site by simply removing the insert, without disassembling the valve stem, valve plate and other parts.

High performance butterfly valves are widely used in power, petrochemical, coal chemical, metallurgy, hydraulic, papermaking, printing and dyeing, light industry and other fields.Also be used for cryogenic, vapor, chlorine gas, oxygen, high vacuum, corrosion and other special conditions.

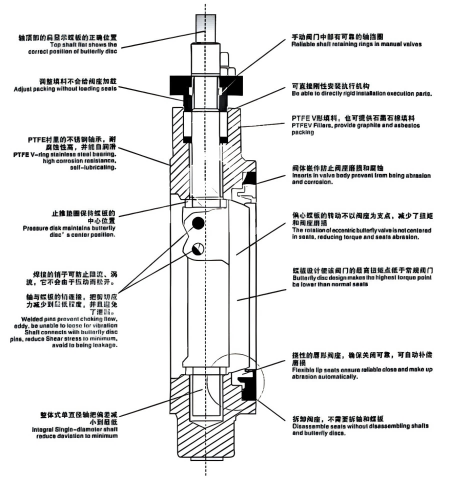

Integral structure of the valve

Product Features

◆Fire- proof structure

Fire-proof valve is tested to API 607 4th Edition and BS 6755 Part Ⅱ

◆Fixed axis

Fixed collar is installed in the top of axis, 2"-24"(DN50- 600). when axis breaks accident, avoid the upper part to move out of gland.

◆Convenient to maintain and upkeep valve seats

Replace axis only by taking inserts down, without disassembling disc and axis.

◆Excellent for both On-Off and Control Application

The design of the sealing ring of the high-performance butterfly valve (PTFE soft seal adopts "lip-tooth" self-sealing structure, and hard seal adopts "U" shaped elastic seal) increases the service life of the valve, and the valve can be opened and closed repeatedly up to millions of times.

◆Bidirectional sealing, zero leakage

Flange High Performance Butterfly Valve

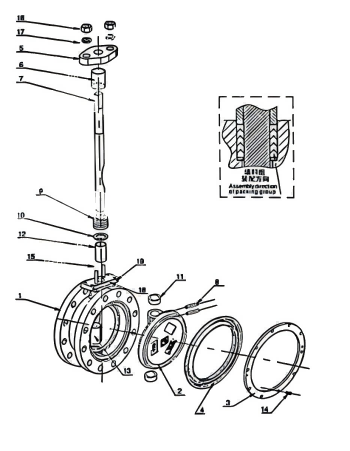

| NO | 名称 Name | 材质 Material |

| 1 | 阀体 Body | WCB,CF8,CF8M,CF3M |

| 2 | 阀板 Plate | CF8,CF8M,CF3M |

| 3 | 嵌件Insert | 20#,304,316,316L |

| 4 | 密封圈 Seal ring | PTFE,RPTFE,PPL |

| 5 | 填料压盖 Packing gland | CF8 |

| 6 | 压圈 Pressing ring | 316 |

| 7 | 阀杆Stem | 17-4PH |

| 8 | 锲销 Pin | 17-4PH |

| 9 | 填料组 Packing group | PTFE,RPTFE,PPL |

| 10 | 填料垫 Packing seat | 316 |

| 11 | 挡圈 Check ring | 316 |

| 12 | 上轴套 Upper shaft sleeve | 316+RPTFE |

| 13 | 下轴套Lower shaft sleeve | 316+RPTFE |

| 14 | 嵌件螺栓Insert bolt | WCB,CF8 |

| 15 | 双头螺栓Stud | GB3098.18.8级 GB3098.1 A2-70级 |

| 16 | 六角螺母Hexagonal nut | GB3098.18.8级 GB3098.1 A2-70级 |

| 17 | 弹簧垫圈Spring washer | WCB,316 |

| 18 | 铭牌Sign | 316 |

| 19 | 铭牌铆打Sign the rivet | 316 |

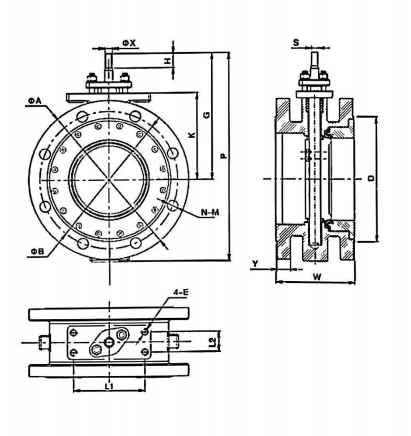

尺寸参数 Size parameters (CLASS150)

| NPS | DN | K | G | P | W | A | B | D | Y | L1 | L2 | E | N | M | H | X | S |

| 3" | 80 | 121 | 213 | 303 | 114 | 190 | 152.4 | 133 | 23 | 125.5 | 22.35 | M10 | 4 | φ19 | 27 | φ15.5 | 11.2 |

| 4" | 100 | 133 | 226 | 331 | 127 | 230 | 190.5 | 162 | 20 | 125.5 | 22.35 | M10 | 8 | φ19 | 27 | φ15.5 | 11.2 |

| 5" | 125 | 135 | 228 | 355 | 140 | 255 | 215.9 | 186 | 22 | 125.5 | 22.35 | M10 | 8 | φ22 | 27 | φ155 | 11.2 |

| 6" | 150 | 152 | 257 | 417 | 140 | 280 | 241.3 | 216 | 23 | 125.5 | 22.35 | M10 | 8 | φ22 | 27 | φ18.8 | 13.9 |

| 8* | 200 | 187 | 295 | 485 | 152 | 345 | 298.5 | 270 | 23 | 125.5 | 22.35 | M10 | 8 | φ22 | 27 | φ21.9 | 15.9 |

| 10" | 250 | 232 | 347 | 569 | 165 | 405 | 362 | 324 | 27 | 142.75 | 37.34 | M12 | 12 | φ26 | 28 | φ28.2 | 20.6 |

| 12“ | 300 | 260 | 380 | 650 | 178 | 485 | 431.8 | 381 | 28 | 142.75 | 37.34 | M12 | 12 | φ26 | 33 | φ34.7 | 23.7 |

| 14“ | 350 | 309 | 443 | 745 | 190 | 535 | 476.3 | 427 | 33 | 142.75 | 37.34 | M12 | 12 | φ29 | 35 | φ34.93 | 28.7 |

| 16” | 400 | 331 | 438.5 | 773.5 | 216 | 595 | 539.8 | 485 | 35 | 203.2 | 82.55 | M16 | 16 | φ29 | 41 | φ46 | 41.4 |

| 18" | 450 | 356 | 517 | 884 | 222 | 635 | 577.9 | 533 | 37 | 203.2 | 82.55 | M16 | 16 | φ32 | 41 | φ47 | 41.4 |

| 20“ | 500 | 377 | 540 | 959 | 229 | 700 | 635 | 584 | 39 | 203.2 | 82.55 | M16 | 20 | φ32 | 41 | φ54.1 | 41.4 |

| 24” | 600 | 490 | 615 | 1046 | 267 | 815 | 749.3 | 692 | 41 | 254 | 82.55 | M20 | 20 | φ35 | 50.8 | φ70 | 50.8 |

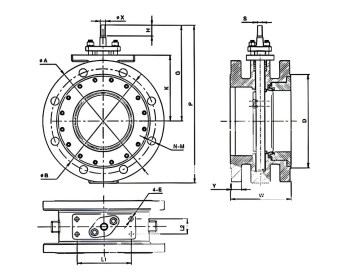

尺寸参数 Size parameters(CLASS300)

| NPS | DN | K | G | P | W | A | B | D | Y | L1 | L2 | E | N | M | H | X | S |

| 3" | 80 | 121 | 213 | 303 | 114 | 190 | 152.4 | 133 | 23 | 125.5 | 22.35 | M10 | 4 | φ19 | 27 | φ15.5 | 11.2 |

| 4" | 100 | 133 | 226 | 331 | 127 | 230 | 190.5 | 162 | 20 | 125.5 | 22.35 | M10 | 8 | φ19 | 27 | φ15.5 | 11.2 |

| 5" | 125 | 135 | 228 | 355 | 140 | 255 | 215.9 | 186 | 22 | 125.5 | 22.35 | M10 | 8 | φ22 | 27 | φ15.5 | 11.2 |

| 6" | 150 | 175 | 257 | 417 | 140 | 300 | 269.9 | 216 | 30 | 125.5 | 22.35 | M10 | 12 | φ22 | 27 | φ21.9 | 15.9 |

| 8* | 200 | 213 | 295 | 485 | 152 | 375 | 330.2 | 270 | 33 | 142.75 | 37.34 | M12 | 12 | φ26 | 28 | φ28.2 | 20.6 |

| 10" | 250 | 254 | 347 | 569 | 165 | 450 | 387.4 | 324 | 38 | 142.75 | 37.34 | M12 | 16 | φ29 | 33 | φ34.7 | 23.7 |

| 12“ | 300 | 283 | 380 | 650 | 178 | 515 | 450.8 | 381 | 40 | 142.75 | 37.34 | M12 | 16 | φ32 | 35 | φ34.93 | 28.7 |

| 14“ | 350 | 355 | 443 | 745 | 190 | 580 | 514.4 | 427 | 42 | 142.75 | 37.34 | M12 | 20 | φ32 | 41 | φ46 | 41.4 |

| 16” | 400 | 350.5 | 438.5 | 773.5 | 216 | 660 | 571.5 | 485 | 44 | 203.2 | 82.55 | M14 | 20 | φ35 | 41 | φ47 | 41.4 |

| 18" | 450 | 424 | 517 | 884 | 222 | 685 | 628.6 | 533 | 46 | 254 | 82.55 | M16 | 24 | φ35 | 41 | φ54.1 | 41.4 |

| 20“ | 500 | 447 | 540 | 959 | 229 | 755 | 685.8 | 584 | 48 | 254 | 82.55 | M20 | 24 | φ35 | 50.8 | φ70 | 50.8 |

| 24” | 600 | 501 | 615 | 1046 | 267 | 890 | 812.8 | 692 | 50 | 254 | 82.55 | M20 | 24 | φ42 | 50.8 | φ83 | 51 |

Helping you with our 10 years experiences of valve products industry