-1.jpg)

-1.jpg)

.jpg)

.jpg)

-1.jpg)

| Face to face: | DIN3202、 BS5163、 ASME B16.10 |

| Manufacturing standards: |

DIN3352、ANSI / AWWA C515-2009、BS5163、BS5150 |

| Flange standard: |

DIN2632-DIN2633、BS4504、EN1092 ASME B16.1 125 pounds or ANSI / AWWA C110 / A21.10 |

| Pressure test standards: | DIN EN 12266-1 |

| Applicable media: | Water |

| Rated operating presure: | PN 1.0/1.6Mpa、150LB |

The soft-sealed gate valve adopts a novel structural design, which overcomes the defects of traditional gate valves such as poor sealing, easy rust and corrosion of internal parts (especially the gate plate), fatigue and aging of rubber elasticity, and the design of this product utilizes the micro deformation of the elastic gate plate Compensation function to achieve a good sealing effect. This product has the characteristics of light switch, good sealing elastic memory and longer service life.

The German standard soft-sealed gate valve adopts a novel structural design. The soft-sealed gate valve overcomes the defects of traditional gate valves such as poor sealing, internal parts, especially the gate plate, which are easy to rust, and rubber elasticity that is fatigued and easy to age. The soft-sealed gate valve has reliable sealing performance, light operation, simple and convenient maintenance, and long service life.

1. Flat bottom valve seat

Traditional gate valves are usually deposited in the groove of the bottom of the valve due to foreign objects such as stones, wood blocks, cement, paper scraps, sundries, etc. after washing the pipe with water, which can easily cause water leakage due to inability to close tightly. The bottom of the soft-sealed gate valve adopts the same flat-bottom design as the water pipe is not easy to cause debris to accumulate, so that the fluid is unobstructed and the flow resistance coefficient is smaller.

2. Overall lagging

The rubber used for the valve plate is covered with rubber as a whole, and the domestic rubber vulcanization technology enables the geometric size of the vulcanized valve plate to be accurate, and the rubber and the ductile iron valve gate are firmly connected, not easy to fall off, and the rubber has better resilience.

3. Ductile iron material

In the past, traditional cast iron gate valves were often broken due to foreign objects hitting, colliding or overlapping. Since the body material of this gate valve is ductile iron, this situation can be greatly reduced.

4.Epoxy resin spraying

Epoxy resin spraying prevents corrosion and rust of the valve body, and can be used in sewage system. The interior of the valve body is coated with epoxy resin, and the inner and outer surfaces of the gate are covered with rubber to avoid rust or corrosion, so it can be used for drinking water pipelines.

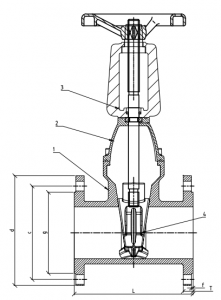

| Item | Part name |

Material |

| 1 | Body |

GGG50 |

| 2 | Bonnet |

GGG50 |

| 3 | Bracket |

GGG50 |

| 4 | Plate |

GGG50+EPDM |

| 5 | Nut | Brass |

| 6 | Guide screw |

2Cr13 |

| 7 | Pressing plate |

5mm steel plate |

| 8 | O-ring |

Silica gel |

| 9 | Handwheel |

GGG50 |

| 10 | Stem nut |

GGG50 |

| 11 | Bolt |

CS |

| 12 | Screw |

Stainless steel |

| SPECIFICATION DIN3352 F4 PN10/16 | ||||||||

| DN | L | a | d | c | x-n | T | f | g |

| 50 | 150 | 50 | 165 | 125 | 4-Φ19 | 16.5 | 2 | 99 |

| 65 | 170 | 65 | 185 | 145 | 4-Φ19 | 17 | 2 | 118 |

| 80 | 180 | 80 | 200 | 160 | 4-Φ19/8-Φ19 | 19 | 3 | 132 |

| 100 | 190 | 100 | 220 | 180 | 8-Φ19 | 20 | 3 | 156 |

| 125 | 200 | 125 | 250 | 210 | 8-Φ19 | 20 | 3 | 184 |

| 150 | 210 | 150 | 285 | 240 | 8-Φ23 | 20 | 3 | 211 |

| 200 | 230 | 200 | 340 | 295 | 8-Φ23/12-Φ23 | 20 | 3 | 266 |

| 250 | 250 | 250 | 405 | 350/355 | 12-Φ23/12-Φ26 | 22 | 3 | 319 |

| 300 | 270 | 300 | 460 | 400/410 | 12-Φ23/12-Φ26 | 25 | 4 | 370 |

| 350 | 290 | 350 | 520 | 460/470 | 16-Φ23/16-Φ26 | 28 | 4 | 430 |

| 400 | 310 | 400 | 580 | 515/525 | 16-Φ25/16-Φ30 | 25/28 | 4 | 475 |

| 450 | 330 | 450 | 615/640 | 565/585 | 20-Φ26/20-Φ30 | 32 | 4 | 565/585 |

| 500 | 350 | 500 | 670/715 | 620/650 | 20-Φ25/20-Φ34 | 27/32 | 4 | 580 |

| 600 | 390 | 600 | 780/840 | 725/770 | 20-Φ30/20-Φ36 | 38 | 4 | 680 |

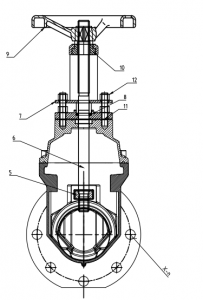

| Item | Part name |

Material |

| 1 | Body |

GGG50/40 |

| 2 | Bonnet |

GGG50/40 |

| 3 | Gland |

GGG50/40 |

| 4 | Disc |

GGG50/40+EPDM |

| 5 | Stem nut | Brass |

| 6 | Stem |

2Cr13 |

| 7 | Pres plate |

5mm steel plate |

| 8 | O-ring |

Silicone |

| 9 | Handwheel |

GGG50 |

| 10 | Bonnet Gasket |

GGG50 |

| 11 | Bolt |

Carbon steel |

| 12 | Bolt |

Stainless steel |

| DIMENSIONS AND WEIGHTS PN10/16 | ||||||||

| DN | L | a | d | c | x-n | T | f | g |

| 50 | 178 | 50 | 165 | 125 | 4-Φ19 | 19 | 3 | 99 |

| 65 | 190 | 65 | 185 | 145 | 4-Φ19 | 19 | 3 | 118 |

| 80 | 203 | 80 | 200 | 160 | 4-Φ19/8-Φ19 | 19 | 3 | 132 |

| 100 | 229 | 100 | 220 | 180 | 8-Φ19 | 19 | 3 | 156 |

| 125 | 254 | 125 | 250 | 210 | 8-Φ19 | 19 | 3 | 184 |

| 150 | 267 | 150 | 285 | 240 | 8-Φ23 | 19 | 3 | 211 |

| 200 | 292 | 200 | 340 | 295 | 8-Φ23/12-Φ23 | 20 | 3 | 266 |

| 250 | 330 | 250 | 395/405 | 350/355 | 12-Φ23/12-Φ26 | 22 | 3 | 319 |

| 300 | 356 | 300 | 445/460 | 400/410 | 12-Φ23/12-Φ26 | 25 | 4 | 370 |

| 350 | 381 | 350 | 505/520 | 460/470 | 16-Φ23/16-Φ26 | 25/27 | 4 | 430 |

| 400 | 406 | 400 | 565/580 | 515/525 | 16-Φ25/16-Φ30 | 25/28 | 4 | 480 |

| 450 | 432 | 450 | 615/640 | 565/585 | 20-Φ26/20-Φ30 | 26/30 | 4 | 530/548 |

| 500 | 457 | 500 | 670/715 | 620/650 | 20-Φ25/20-Φ34 | 27/32 | 4 | 582/609 |

| 600 | 508 | 600 | 780/840 | 725/770 | 20-Φ31/20-Φ37 | 30/36 | 5 | 682/720 |

| 700 | 610 | 400 | 895/910 | 840 | 24-Φ31/21-Φ37 | 33/40 | 5 | 794 |

| 800 | 660 | 450 | 1015/1025 | 950 | 24-Φ34/24-Φ40 | 35/43 | 5 | 901 |

| 900 | 711 | 500 | 1115/1125 | 1050 | 28-Φ34/28-Φ40 | 38/47 | 5 | 1001 |

| 1000 | 811 | 600 | 1230/1255 | 1160/1170 | 28-Φ37/28-Φ48 | 40/50 | 5 | 1112 |

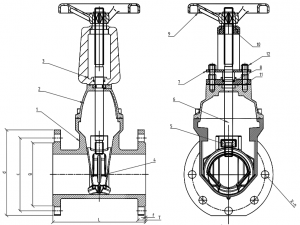

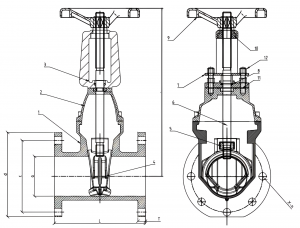

| Item | Part name |

Material |

| 1 | Body |

GGG50/40 |

| 2 | Bonnet |

GGG50/40 |

| 3 | Stent |

GGG50/40 |

| 4 | Disc |

GGG50/40+EPDM |

| 5 | Stem nut | GGG50/40 |

| 6 | Stem |

2Cr13 |

| 7 | Platen |

5mm steel plate |

| 8 | O-ring |

Silica gel |

| 9 | Handwheel |

GGG50/40 |

| 10 | Lifting mother |

GGG50 |

| 11 | Bolt |

Carbon steel |

| 12 | Bolt |

Stainless steel |

| Technical Parameters AWWA C515 150LB | ||||||||

| DN | L | H | a | d | c | x-n | T | |

| 50 | 178 | 320 | 50 | 152 | 120.5 | 4-Φ19 | 16 | |

| 65 | 190 | 370 | 65 | 178 | 139.5 | 4-Φ19 | 17.5 | |

| 80 | 203 | 410 | 80 | 191 | 152.5 | 4-Φ19 | 19 | |

| 100 | 229 | 480 | 100 | 229 | 190.5 | 8-Φ19 | 24 | |

| 125 | 254 | 560 | 125 | 254 | 216 | 8-Φ22 | 24 | |

| 150 | 267 | 640 | 150 | 279 | 241.5 | 8-Φ22 | 25.5 | |

| 200 | 292 | 810 | 200 | 343 | 298.5 | 8-Φ22 | 29 | |

| 250 | 330 | 950 | 250 | 406 | 362 | 12-Φ25 | 30.5 | |

| 300 | 356 | 1050 | 300 | 483 | 432 | 12-Φ25 | 32 | |

| 350 | 381 | 1200 | 350 | 533 | 476 | 12-Φ29 | 35 | |

| 400 | 406 | 1360 | 400 | 597 | 539.5 | 16-Φ29 | 37 | |

| 450 | 432 | 1540 | 450 | 635 | 577.9 | 16-Φ32 | 39.7 | |

| 500 | 457 | 1650 | 500 | 699 | 635 | 20-Φ32 | 43 | |

| 600 | 508 | 1980 | 600 | 813 | 749.5 | 20-Φ35 | 48 | |

Water treatment, HVAC, Urban construction, Petroleum, Chemical Indsutry, Textile & Papermaking

Helping you with our 10 years experiences of valve products industry