Pneumatic actuator is an actuator device that uses air source to pressure-drive the opening and closing or regulating valve. Compared with electric actuators, pneumatic actuators perform very fast. Pneumatic actuators are divided into single-acting and double-acting according to different forms of action, and the differences and principles of the two are also different!

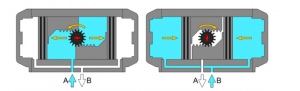

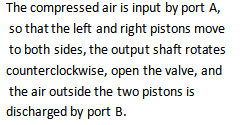

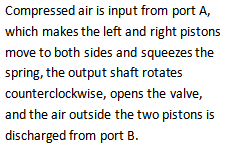

Double-acting actuators are mainly air-opening-air-closing, that is, the valve needs to use air source whether it is opening or closing. Usually, the ventilation is opened, the ventilation is closed, the air source is lost, the valve remains in the current state, and the valve can continue to work only after the air source is reconnected.

Double acting (top view)

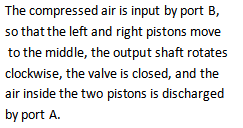

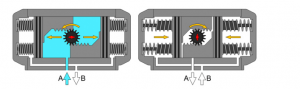

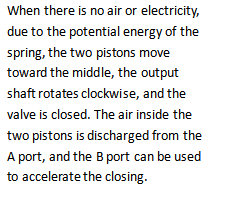

Single acting pneumatic actuator has the function of spring return, and the user can choose the normally open type and the normally closed type according to the needs of the working conditions.

Situation 1: When the ventilation is open and the air source is lost, it will automatically reset to the initial closed state.

Situation 2: When the ventilation is closed and the air source is lost, it will automatically reset to the initial open state.

Single acting (top view)

Double-acting pneumatic actuators are generally used in working conditions that do not require high leakage, while single-acting pneumatic actuators are used in dangerous working conditions, it can quickly close or open the valve when the air source is lost when there is a sudden failure. In terms of price, single-acting pneumatic actuators will be higher than double-acting.