| Face to Face: |

API609 |

| Test and Inspection: |

API598 |

| Top Flange Standard: |

ISO5211 |

| Epoxy Spraying: |

RAL customized series |

| Documents Service: |

FORM E Certificate of Origin/Certificate of Material/Pressure Testing Report |

| Working Temperature: |

Carbon steel:-29℃~425℃, Stainless steel:-40℃~600℃ |

|

Nominal Pressure: |

PN6/PN10/PN16/PN25 |

|

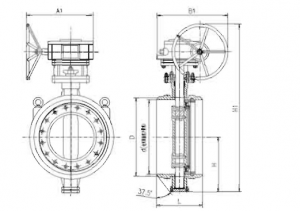

Three Eccentric Butterfly Valve |

|

| Body Material: |

ASTM A216 WCB/CF8/CF8M |

| Disc Material: |

ASTM A216 WCB/CF8/CF8M |

| Shaft Material: |

2Cr13 |

| Seat Material: |

Stainless steel+graphite/PTFE |

The welded metal hard seal butterfly valve adopts triple eccentric structure. This valve is designed to be an ideal hard seal butterfly valve for bubble grade seals in high temperature, high pressure, and fire protection applications. Due to the welded structure, the valve and the pipeline plane achieve permanent zero leakage. The welded butterfly valve has no flange, which brings great convenience to the insulation and bandaging of the pipeline.

| 公称压力 Nominal pressure PN1.0 MPa | ||||||||

| DN | Technical Dimension Information | WT(kg) | ||||||

| mm | L | D | d | H | H1 | A | B | |

| 600 | 390 | 636 | 602 | 499 | 1280 | 570 | 660 | 465 |

| 700 | 430 | 726 | 692 | 566 | 1480 | 750 | 550 | 680 |

| 800 | 470 | 826 | 792 | 632 | 1608 | 750 | 550 | 810 |

| 900 | 510 | 926 | 892 | 693 | 1857 | 750 | 550 | 860 |

| 1000 | 550 | 1028 | 992 | 757 | 2038 | 900 | 750 | 1625 |

| 1200 | 630 | 1228 | 1392 | 851 | 2237 | 1000 | 925 | 1770 |

| 1400 | 710 | 1428 | 1392 | 876 | 2411 | 1000 | 925 | 2425 |

| 1600 | 790 | 1628 | 1592 | 1095 | 2756 | 1000 | 925 | 3560 |

| 1800 | 870 | 1828 | 1792 | 1214 | 3093 | 1100 | 980 | 4545 |

| 2000 | 950 | 2028 | 1992 | 1332 | 3355 | 1100 | 980 | 6230 |

| 公称压力 Nominal pressure PN1.6MPa | ||||||||

| DN | Technical Dimension Information | WT(kg) | ||||||

| mm | L | D | d | H | H1 | A | B | |

| 80 | 114 | 90 | 78 | 90 | 356 | 180 | 200 | 27 |

| 100 | 127 | 110 | 96 | 100 | 375 | 180 | 200 | 34 |

| 125 | 140 | 135 | 121 | 113 | 401 | 180 | 200 | 41 |

| 150 | 210 | 161 | 146 | 130 | 450 | 270 | 280 | 43 |

| 200 | 230 | 222 | 202 | 205 | 545 | 400 | 425 | 81 |

| 250 | 250 | 278 | 254 | 235 | 630 | 400 | 425 | 102 |

| 300 | 270 | 330 | 303 | 275 | 715 | 450 | 560 | 132 |

| 350 | 290 | 382 | 351 | 309 | 817 | 450 | 560 | 164 |

| 400 | 310 | 432 | 398 | 346 | 923 | 535 | 580 | 193 |

| 450 | 330 | 484 | 450 | 392 | 1059 | 535 | 580 | 238 |

| 500 | 350 | 535 | 501 | 427 | 1126 | 535 | 580 | 302 |

| 600 | 390 | 636 | 602 | 509 | 1369 | 570 | 660 | 457 |

| 700 | 430 | 726 | 692 | 572 | 1492 | 750 | 550 | 810 |

| 800 | 470 | 826 | 792 | 638 | 1622 | 750 | 550 | 1093 |

| 900 | 510 | 926 | 892 | 700 | 1924 | 750 | 550 | 1410 |

| 1000 | 550 | 1028 | 992 | 765 | 2054 | 900 | 750 | 1870 |

| 1200 | 630 | 1228 | 1192 | 860 | 2259 | 1000 | 925 | 2082 |

| 1400 | 710 | 1428 | 1392 | 986 | 2610 | 1000 | 925 | 2850 |

| 1600 | 790 | 1628 | 1592 | 1106 | 2856 | 1000 | 925 | 4235 |

| 1800 | 870 | 1828 | 1792 | 1226 | 3121 | 1100 | 980 | 5346 |

| 2000 | 950 | 2028 | 1992 | 1345 | 3385 | 1100 | 980 | 7328 |

| 公称压力 Nominal pressure PN2.5MPa | ||||||||

| DN | Technical Dimension Information | WT(kg) | ||||||

| mm | L | D | d | H | H1 | A | B | |

| 80 | 114 | 90 | 78 | 90 | 356 | 180 | 200 | 38 |

| 100 | 127 | 110 | 96 | 106 | 387 | 180 | 200 | 40 |

| 125 | 140 | 135 | 121 | 122 | 413 | 180 | 200 | 60 |

| 150 | 210 | 161 | 146 | 136 | 459 | 270 | 280 | 65 |

| 200 | 230 | 222 | 202 | 215 | 585 | 400 | 425 | 85 |

| 250 | 250 | 278 | 254 | 247 | 649 | 400 | 425 | 135 |

| 300 | 270 | 330 | 303 | 288 | 771 | 450 | 560 | 175 |

| 350 | 290 | 382 | 351 | 333 | 929 | 450 | 560 | 195 |

| 400 | 310 | 432 | 398 | 359 | 993 | 535 | 580 | 295 |

| 450 | 330 | 484 | 450 | 405 | 1053 | 535 | 580 | 350 |

| 500 | 350 | 535 | 501 | 444 | 1245 | 535 | 580 | 510 |

| 600 | 390 | 636 | 602 | 521 | 1750 | 570 | 660 | 625 |

| 700 | 430 | 726 | 692 | 586 | 1519 | 750 | 550 | 925 |

| 800 | 470 | 826 | 792 | 659 | 1659 | 750 | 550 | 1260 |

| 900 | 510 | 926 | 892 | 720 | 1829 | 750 | 550 | 1790 |

| 1000 | 550 | 1028 | 992 | 780 | 1949 | 900 | 750 | 1940 |

| 1200 | 630 | 1228 | 1192 | 889 | 2243 | 1000 | 925 | 2810 |

| 1400 | 710 | 1428 | 1392 | 1000 | 2262 | 1000 | 925 | 3500 |

1. Compact structure, small volume, light weight, flexible operation, easy to use;

2.Using triple eccentric hard sealing structure, multi-level reliable sealing performance to achieve zero leakage;

3. This valve has no flange, which brings great convenience and beauty to the heat preservation of the pipeline;

4. It has the characteristics of high temperature resistance, high pressure resistance, corrosion resistance and wear resistance.

Welding type metal hard seal butterfly valve is widely used in heat, petroleum, chemical, electric power, metallurgy, food, medicine, textile, paper and other industries, can be installed in the temperature ≤425℃, medium for gas, air, steam, water, sea water, oil and other industrial pipe network for regulating flow and cut off media.

Helping you with our 10 years experiences of valve products industry