| Face to Face: |

API609 |

| Test and Inspection: |

API598 |

| Top Flange Standard: |

ISO5211 |

| Epoxy Spraying: |

RAL 5005 or customized |

| Documents Service: |

FORM E Certificate of Origin/Certificate of Material/Pressure Testing Report |

| Working Temperature: |

-20℃~120℃ |

|

Nominal Pressure: |

PN10/PN16/CLASS125/CLASS150/10K/5K |

|

Available Material: |

|

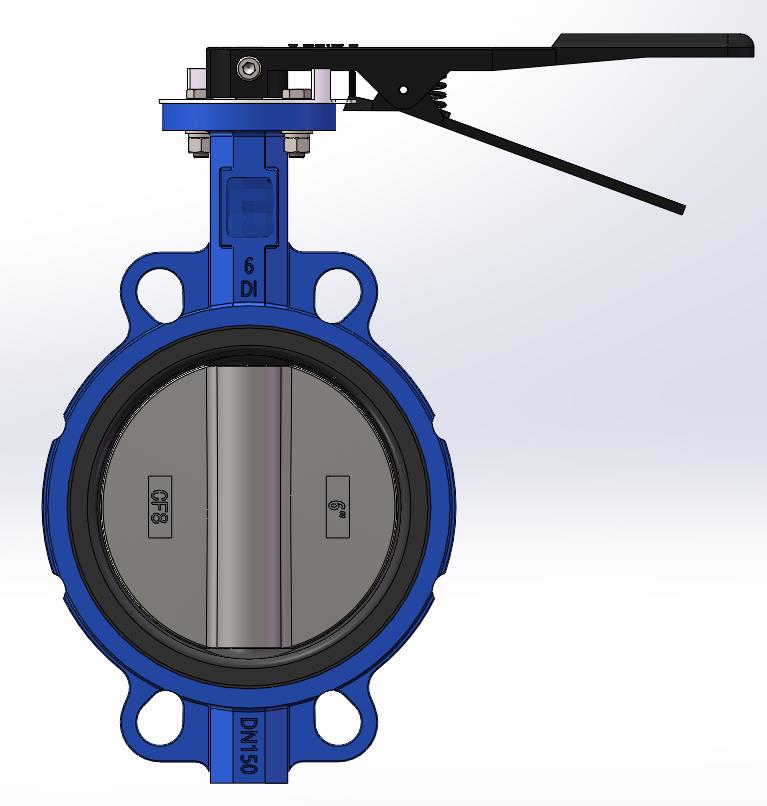

| Body Material: |

Ductile Iron |

| Disc Material: |

Ductile iron/CF8/CF8M/CF3/CF3M/1.4529/AL.Bronze C954 or C958 |

| Shaft Material: |

SS416/SS420/SS304/SS316/SS431 |

| Seat Material: |

EPDM/NBR/Viton/PTFE |

|

Quality Standard: |

|

| Design & Manufacture Standard: |

API 609 |

| Face to Face Dimension Standard: |

API 609 |

| Test & Inspection Standard: |

API 598 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

B |

φD2 |

φD3 |

n-φd |

|

|

1.5″ |

DN40 |

33 |

69 |

65 |

127 |

25 |

9 |

65 |

50 |

4-8 |

|

2″ |

DN50 |

42 |

73.3 |

75 |

129 |

25 |

9 |

65 |

50 |

4-8 |

|

2.5″ |

DN65 |

44 |

86 |

82 |

136 |

25 |

9 |

65 |

50 |

4-8 |

|

3″ |

DN80 |

45 |

100.9 |

99 |

153 |

25 |

9 |

65 |

50 |

4-8 |

|

4″ |

DN100 |

51.5 |

132 |

110 |

167 |

28 |

11 |

90 |

70 |

4-10 |

|

5″ |

DN125 |

54 |

156 |

125 |

193 |

28 |

14 |

90 |

70 |

4-10 |

|

6″ |

DN150 |

55 |

185 |

145 |

209 |

28 |

14 |

90 |

70 |

4-10 |

|

8″ |

DN200 |

59 |

235 |

170 |

251 |

33 |

17 |

125 |

102 |

4-12 |

|

10″ |

DN250 |

66 |

289 |

210 |

280 |

33 |

22 |

125 |

102 |

4-12 |

|

12″ |

DN300 |

76 |

341 |

240 |

312 |

33 |

22 |

125 |

102 |

4-12 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

φd |

φD2 |

φD3 |

n-φd1 |

N-b |

K |

|

|

16″ |

DN400 |

86.5 |

436 |

320 |

403 |

52 |

33.15 |

175 |

140 |

4-18 |

1-10 |

36.2 |

|

18″ |

DN450 |

104.6 |

487 |

351 |

415 |

52 |

38 |

175 |

140 |

4-18 |

1-10 |

41 |

|

20″ |

DN500 |

130 |

532 |

386 |

466 |

64 |

41.15 |

175 |

140 |

4-18 |

1-12 |

44.2 |

|

24″ |

DN600 |

152 |

651 |

446 |

525 |

70 |

50.65 |

210 |

165 |

4-22 |

1-16 |

54.7 |

|

28″ |

DN700 |

163 |

741 |

520 |

618 |

95 |

63.35 |

300 |

254 |

8-18 |

2-18 |

71.4 |

|

32″ |

DN800 |

188 |

847 |

580 |

665 |

95 |

63.35 |

300 |

254 |

8-18 |

2-18 |

71.4 |

|

36″ |

DN900 |

203 |

971 |

670 |

720 |

130 |

75 |

300 |

254 |

8-18 |

2-20 |

84 |

|

40″ |

DN1000 |

216 |

1050 |

735 |

800 |

130 |

85 |

300 |

254 |

8-18 |

2-22 |

95 |

|

48″ |

DN1200 |

276 |

1261 |

878 |

940 |

150 |

105 |

350 |

298 |

8-22 |

2-28 |

117 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

B |

φD2 |

φD3 |

n-φd |

φD4 |

|

|

1.5″ |

DN40 |

33 |

69 |

65 |

127 |

14 |

9 |

65 |

50 |

4-8 |

135 |

|

2″ |

DN50 |

42 |

73.3 |

75 |

129 |

14 |

9 |

65 |

50 |

4-8 |

135 |

|

2.5″ |

DN65 |

44 |

86 |

82 |

136 |

18 |

9 |

65 |

50 |

4-8 |

135 |

|

3″ |

DN80 |

45 |

100.9 |

99 |

153 |

18 |

9 |

65 |

50 |

4-8 |

135 |

|

4″ |

DN100 |

51.5 |

132 |

110 |

167 |

20 |

11 |

90 |

70 |

4-10 |

135 |

|

5″ |

DN125 |

54 |

156 |

125 |

193 |

20 |

14 |

90 |

70 |

4-10 |

135 |

|

6″ |

DN150 |

55 |

185 |

145 |

209 |

25 |

14 |

90 |

70 |

4-10 |

135 |

|

8″ |

DN200 |

59 |

235 |

170 |

251 |

25 |

17 |

125 |

102 |

4-12 |

270 |

|

10″ |

DN250 |

66 |

289 |

210 |

280 |

30 |

22 |

125 |

102 |

4-12 |

270 |

|

12″ |

DN300 |

76 |

341 |

240 |

312 |

30 |

22 |

125 |

102 |

4-12 |

270 |

|

14″ |

DN350 |

76 |

372 |

271 |

327 |

40 |

22 |

125 |

102 |

4-12 |

270 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

B |

φD2 |

φD3 |

n-φd |

φD4 |

|

|

1.5″ |

DN40 |

33 |

69 |

65 |

127 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

2″ |

DN50 |

42 |

73.3 |

75 |

129 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

2.5″ |

DN65 |

44 |

86 |

82 |

136 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

3″ |

DN80 |

45 |

100.9 |

99 |

153 |

25 |

9 |

65 |

50 |

4-8 |

135 |

|

4″ |

DN100 |

51.5 |

132 |

110 |

167 |

28 |

11 |

90 |

70 |

4-10 |

135 |

|

5″ |

DN125 |

54 |

156 |

125 |

193 |

28 |

14 |

90 |

70 |

4-10 |

135 |

|

6″ |

DN150 |

55 |

185 |

145 |

209 |

28 |

14 |

90 |

70 |

4-10 |

135 |

|

8″ |

DN200 |

59 |

235 |

170 |

251 |

33 |

17 |

125 |

102 |

4-12 |

270 |

|

10″ |

DN250 |

66 |

289 |

210 |

280 |

33 |

22 |

125 |

102 |

4-12 |

270 |

|

12″ |

DN300 |

76 |

341 |

240 |

312 |

33 |

22 |

125 |

102 |

4-12 |

270 |

|

14″ |

DN350 |

76 |

372 |

271 |

327 |

45 |

22 |

125 |

102 |

4-12 |

270 |

|

DN |

L |

D1 |

L1 |

L2 |

L3 |

φd |

φD2 |

φD3 |

n-φd1 |

N-b |

K |

|

|

16″ |

DN400 |

86.5 |

436 |

320 |

403 |

52 |

33.15 |

175 |

140 |

4-18 |

1-10 |

36.2 |

|

18″ |

DN450 |

104.6 |

487 |

351 |

415 |

52 |

38 |

175 |

140 |

4-18 |

1-10 |

41 |

|

20″ |

DN500 |

130 |

532 |

386 |

466 |

64 |

41.15 |

175 |

140 |

4-18 |

1-12 |

44.2 |

|

24″ |

DN600 |

152 |

651 |

446 |

525 |

70 |

50.65 |

210 |

165 |

4-22 |

1-16 |

54.7 |

|

28″ |

DN700 |

163 |

741 |

520 |

618 |

95 |

63.35 |

300 |

254 |

8-18 |

2-18 |

71.4 |

|

32″ |

DN800 |

188 |

847 |

580 |

665 |

95 |

63.35 |

300 |

254 |

8-18 |

2-18 |

71.4 |

|

36″ |

DN900 |

203 |

971 |

670 |

720 |

130 |

75 |

300 |

254 |

8-18 |

2-20 |

84 |

|

40″ |

DN1000 |

216 |

1050 |

735 |

800 |

130 |

85 |

300 |

254 |

8-18 |

2-22 |

95 |

|

48″ |

DN1200 |

276 |

1261 |

878 |

940 |

150 |

105 |

350 |

298 |

8-22 |

2-28 |

117 |

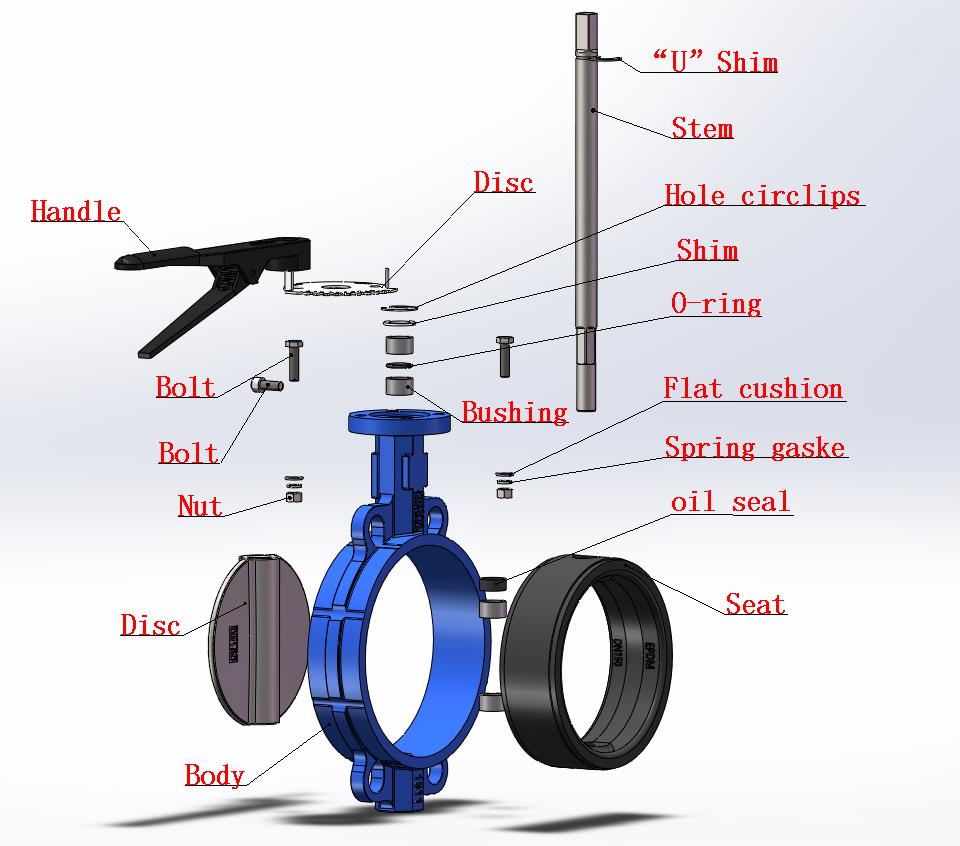

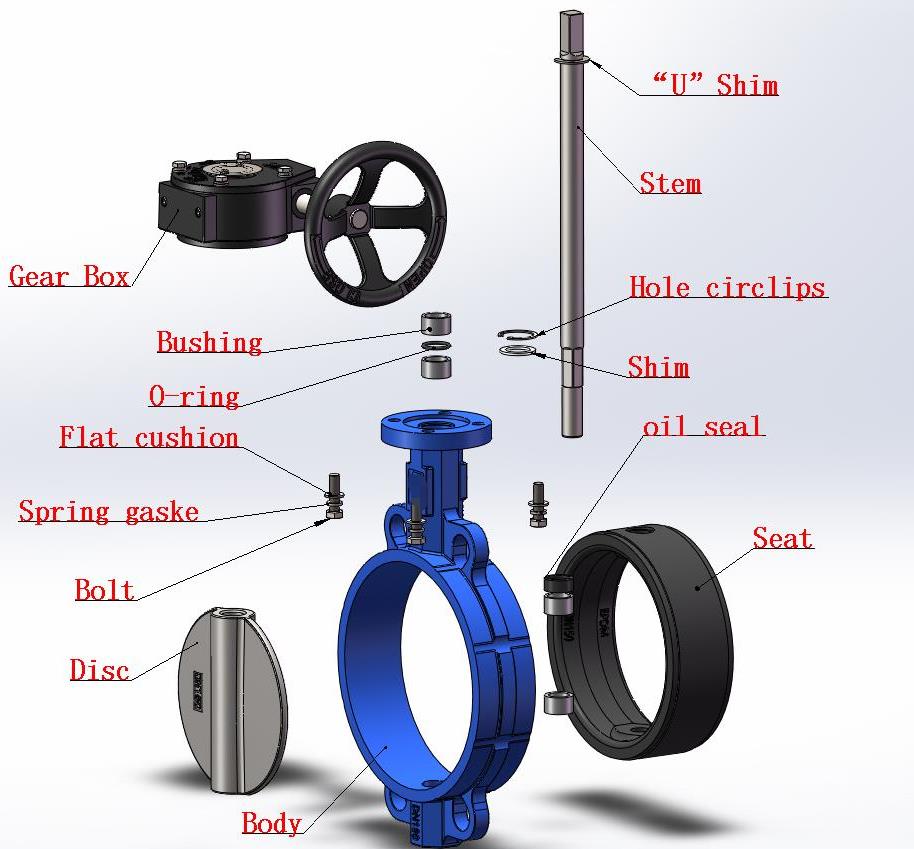

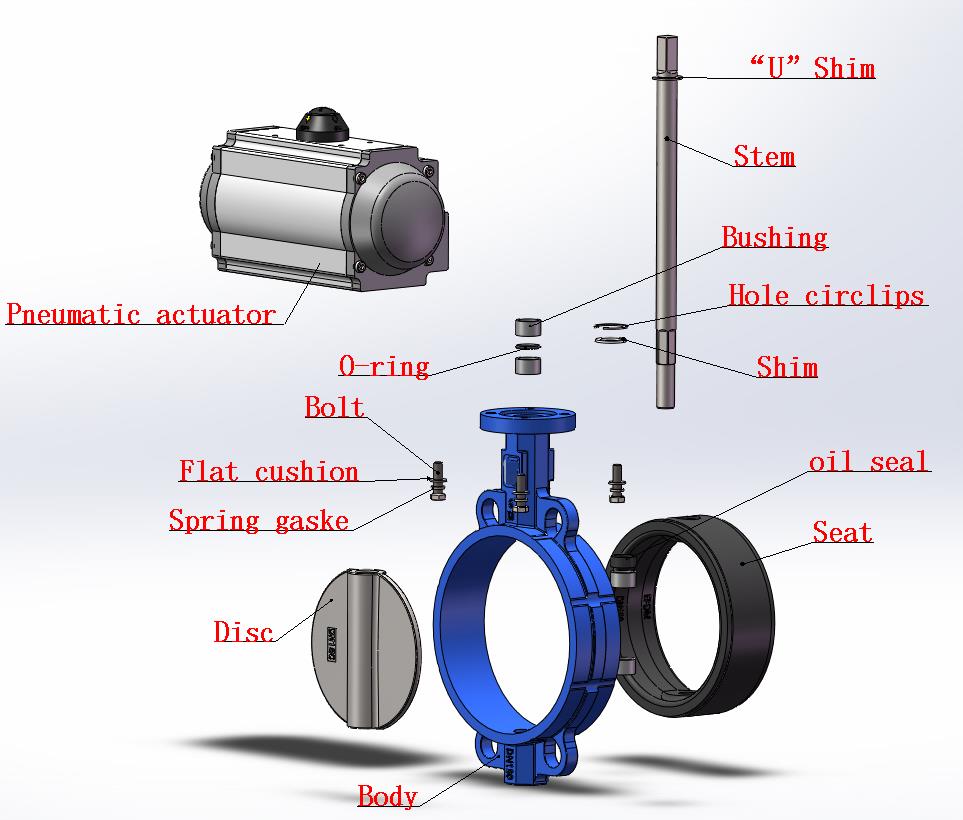

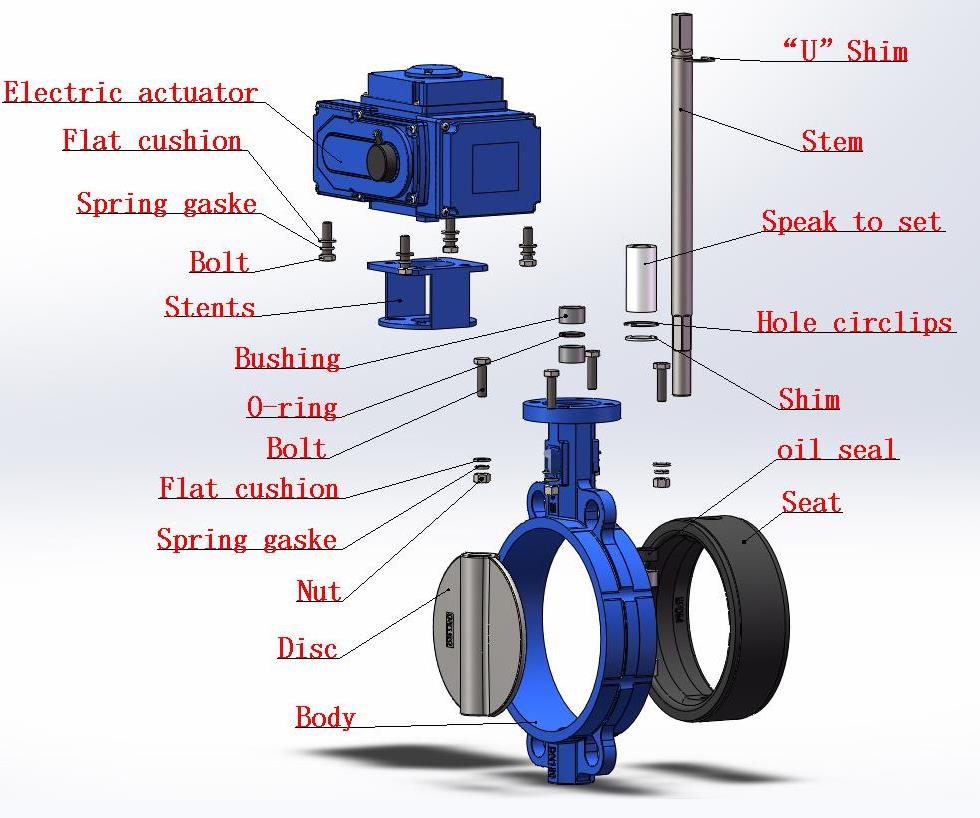

1.High performance seat rubber(50% rubber content).

2.EPDM soft seated which can be replaced when demaged.

3.Valve switch life-time is more than 30000 times.

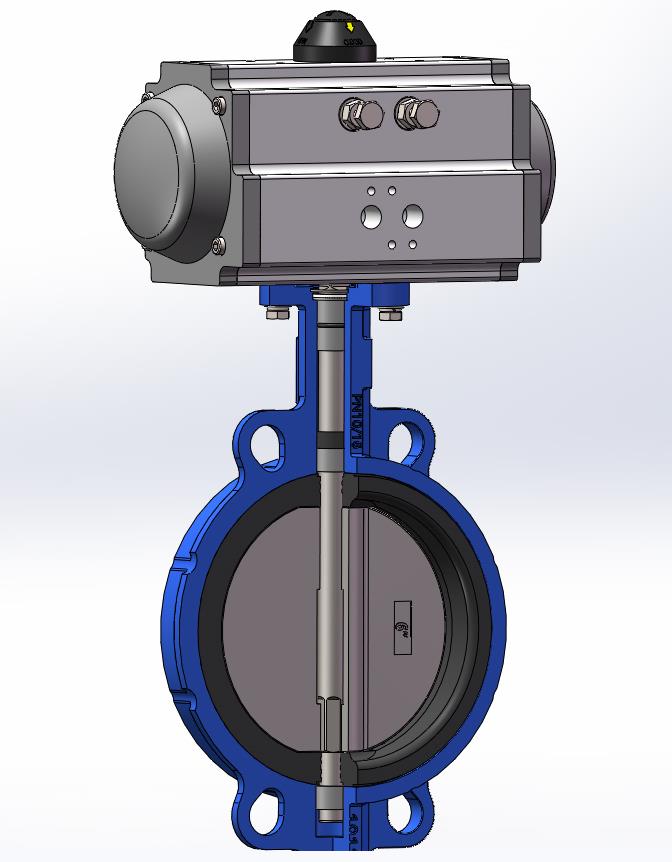

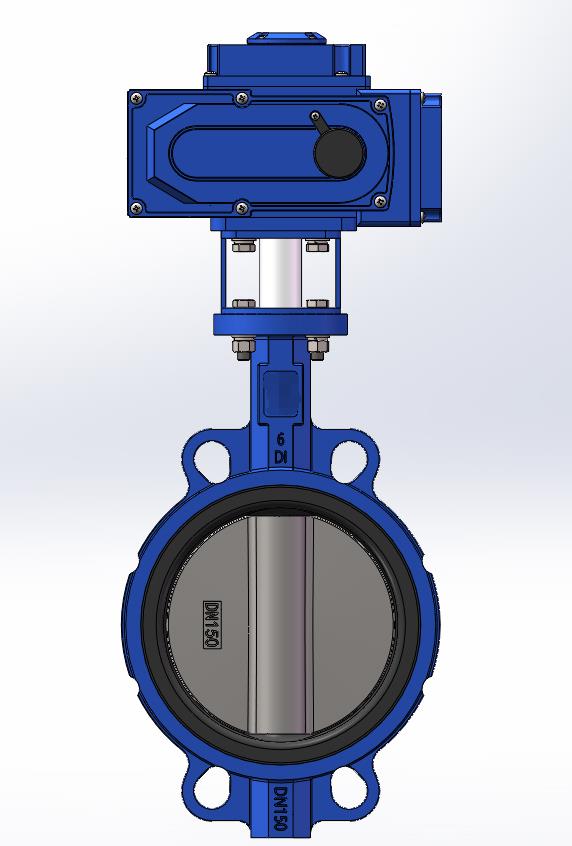

4.Axial seal(O-ring+oil seal,double seal structure).

5.Adopt epoxy spraying(stronger adhesion and good weather resistance).

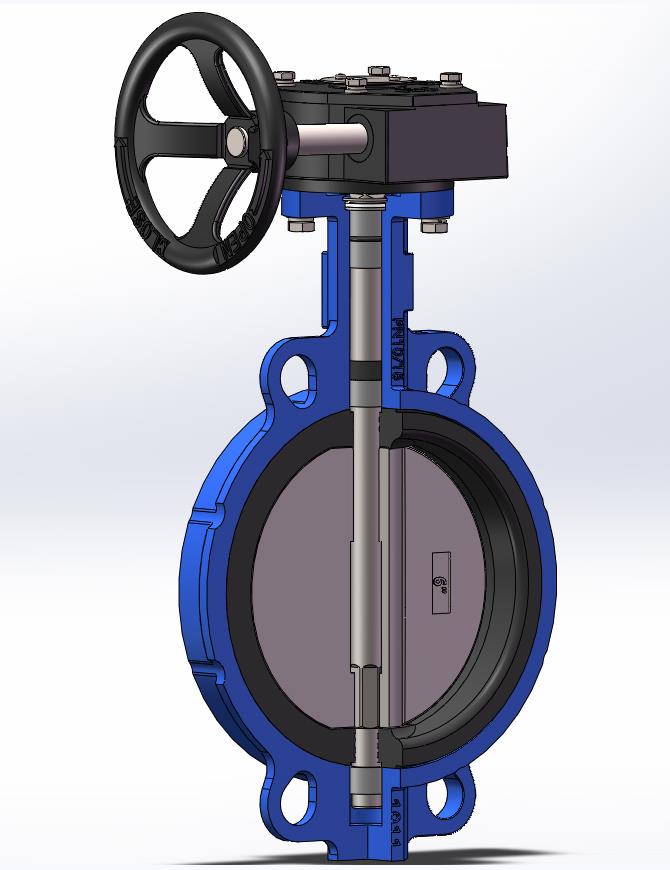

6.Ductile Iron Lever&Worm Gear(stronger corrosion resistance).

7.Pneumatic Actuator adopts double piston rack structure.

8.Electric Actuator supplying voltage: 380V,220V or customized.

9.Pressure Testing Report,Certificate of Material and FORM E Certificate Of Origin can be provided.

Water supply and drainage, Tap Water, Sewage, Power station, Boiler steam systems, Urban construction, Petroleum, Chemical Indsutry, Municipal administration

Helping you with our 10 years experiences of valve products industry